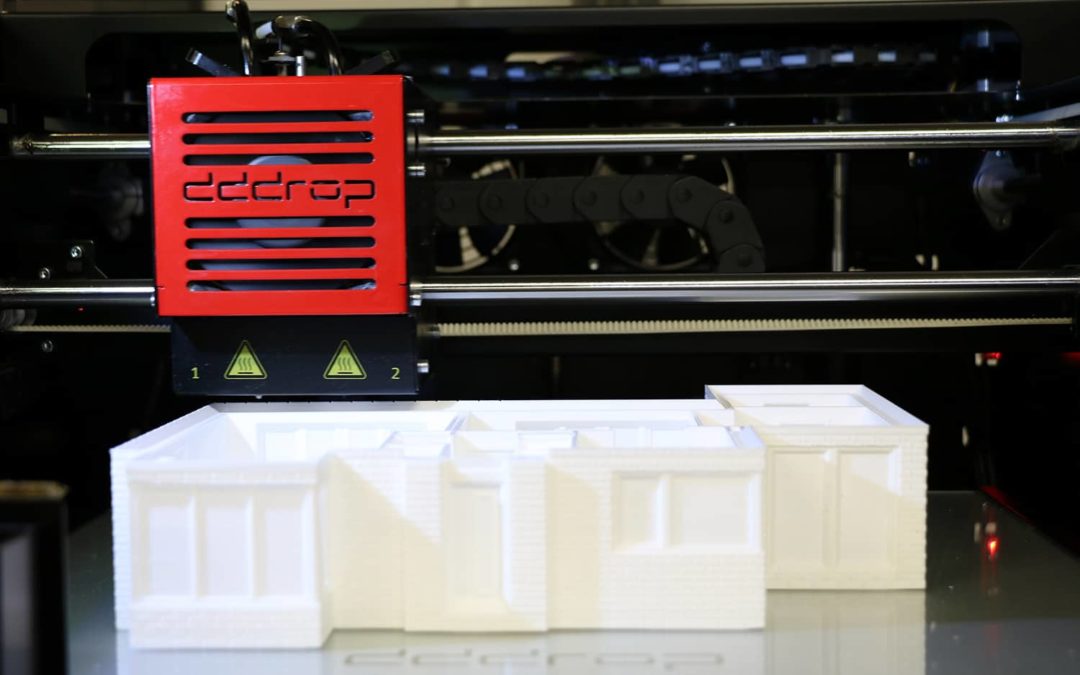

3D printing with support material

When do you need to 3D print with support material?

Support with the original material

Supporting with PVA filament

Supporting with PVA+ filament

Supporting with the original material

Supporting with PVA filament

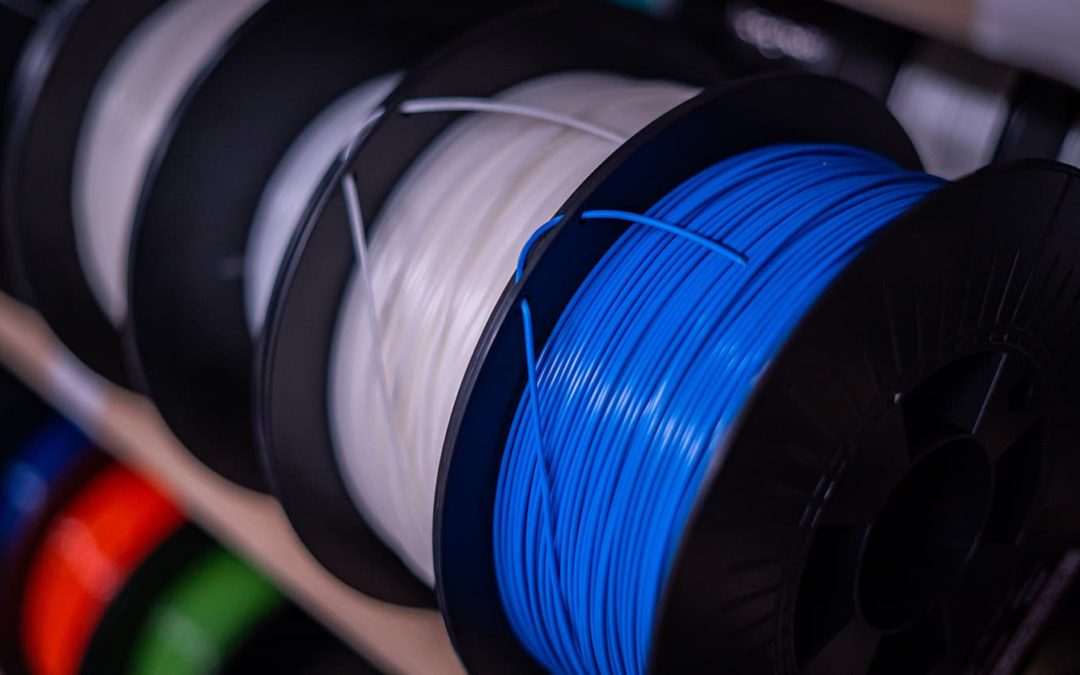

PVA stands for polyvinyl alcohol and is a soft and biodegradable polymer that is very sensitive to moisture. When PVA is exposed to water, it will dissolve. Therefore, it is perfect as a carrier material for 3D printing. After printing, the filament can be easily removed by dissolving it in cold or lukewarm water. PVA is often used in conjunction with PLA filament, but is now increasingly being applied to other filaments such as PET-G. In addition, there are several new modifications that make it possible to use PVA with higher temperatures. For example, we are talking about PVA+.

Supporting with PVA+ filament

The major advantage of printing with support material is that it is easily removed without leaving parts behind or damaging the 3D model. A disadvantage is that support filaments are often more expensive than the base filament and can only be printed on a 3D printer with a dual extruder. dddrop also sells its own support material for the best printing results.

3D design and 3D printing

How to design and print a perfect 3D model?

That engineer is a special and great profession needs no further explanation. All objects around us were once developed by an engineer. For years we all produced mainly with the well-known techniques such as mill-turning or injection molding. Meanwhile, the 3D printer has made its appearance in the manufacturing industry and this also requires a change in development: designing for a 3D print requires a new way of thinking.

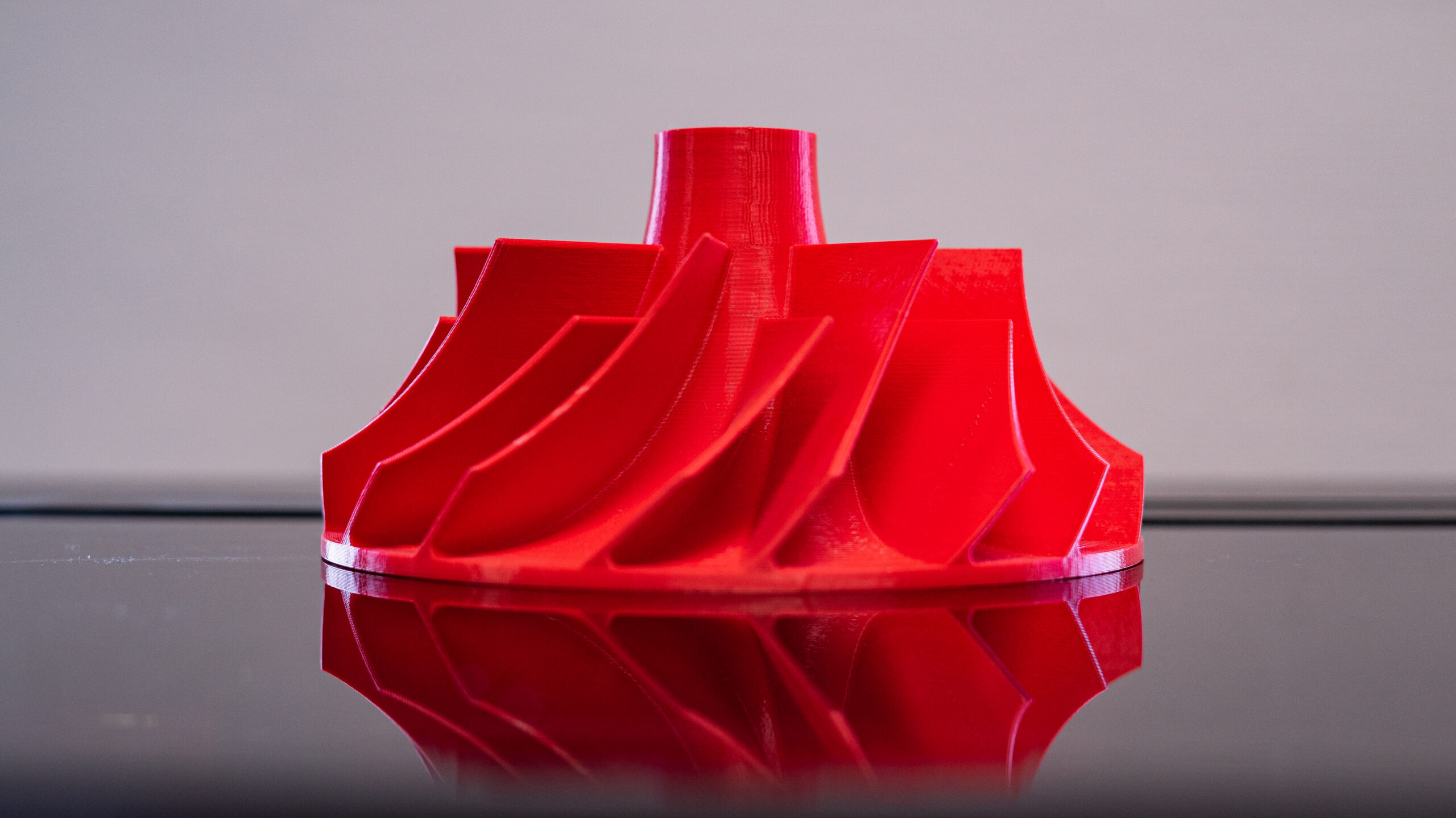

With traditional techniques, development usually starts with a piece of material from which parts are removed until the desired product is achieved. With 3D printing, development begins with an empty space. This empty space is the engineer’s new starting point, as the 3D model is built from layers. What does this mean for the design and printing process?

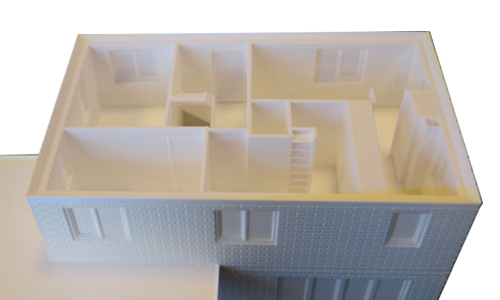

Making a 3D model

First of all, we require a 3D drawing of the product or part. There are several 3D CAD software packages available for creating the 3D design, like SOLIDWORKS. You can learn how to draw simple models relatively quick, there are various trainings available that teach the basics.

Make it 3D printable

When the 3D drawing is ready, it needs to be converted into a printable 3D file: a so-called .STL file. Several software packages, like Simplify3D, convert 3D drawings into a layer-based model. You basically don’t need to do anything about it, but of course it is possible to adjust some settings to tailor it to -for instance- the material (filament) you’ll be using.

Important aspects to take into account during the design and printing process are:

Thin walls

problems could arise when layers smaller than the nozzle size need to be printed. When a wall of 0.2mm has to be printed with a 0.4mm nozzle, this thin wall will not be shown in the Simplify3D preview and not be printed. Read more about printing thin-walled products.

Tip: always scale in the CAD program (instead of the slicing software) for the best result.

Support material

Assemblies

Bridging

Tolerance

When printing two parts that need to fit together, like a bolt/nut construction, you need to take the shrinking of the material into account. It’s usually enough to use a tolerance of ±0.1mm, but this can differ per model.

How thin can a 3D printer print?

How thin can a 3D printer print?

Explore the limits of 3D printing technology as we delve into the question: how thin can a 3D printer print? This guide unfolds the intricacies of achieving fine prints, shedding light on nozzle sizes, wall thickness, and the tweaks that can make all the difference.

With FDM printing, a model is constructed by printing layers of filament (plastic). This filament is heated until it melts and is then guided through the nozzle of the printer. The width of the layer that is printed onto the print bed is partly determined by the size of the nozzle. Several sizes are available, to enable printing different wall thicknesses (extrusion widths). When printing thin-walled models, it’s good to know how this exactly works. When the wrong settings are used, it could happen that a wall isn’t constructed correctly or not even printed at all. This often happens when models are scaled down.

Different nozzle sizes

The various nozzle sizes can be used for different purposes. Do you want a model to be printed quickly, without paying too much attention to the details? Then choose a big nozzle size like 1.0mm. This nozzle prints a wide and high layer, resulting in less required layers and therefore a quicker result. However, if you want to print a detailed or thin-walled model, you should choose a smaller nozzle, like 0.2 or 0.4mm.

Too thin walls

Change the design

Change the nozzle

Material considerations for thin printing

Software settings for optimized thin printing

Common challenges and solutions in thin printing

Conclusion

FAQ

How thin is too thin for a 3D printer?

The minimum thickness a 3D printer can achieve is determined by its hardware, particularly the nozzle size. For a standard 0.4 mm nozzle, the thinnest line it can technically print is 0.24 mm, which is achieved by adjusting the line width parameter in the slicing software. There are experimental settings in some slicing software like Cura that might allow for printing thinner walls, but they come with their own set of challenges.

What is the thinnest layer a 3D printer can print?

The thinnest layer height, or Z resolution, is typically around 0.025 mm or 25 microns for SLA 3D printers, and around 0.1 mm or 100 microns for FDM 3D printers.

Is 0.2 mm good for 3D printing?

A 0.2 mm layer height is a common setting for FDM 3D printers when a balance between detail and printing time is desired. It provides a good level of detail while not being as time-consuming as finer layer heights like 0.1 mm.

What is the minimum line thickness for 3D printing?

The minimum line thickness for 3D printing is often equated to the nozzle diameter of the 3D printer. For instance, with a 0.4 mm nozzle, a minimum line width of 0.24 mm is achievable.

Printing a 3D model that sticks

Printing a 3D model that sticks

FDM 3D printing technology uses molten filament (plastic) that is printed onto the print bed through the nozzle. For a perfectly printed model, it is crucial that the first layer of filament adheres well to the print bed. Most filaments tend to warp when the material cools too quickly, especially on the print bed. So, without proper adhesion to the bed, the filament will warp, making the product deformed and unusable. There are several ways to prevent this: the biggest benefit comes from using a heated print bed.

Temperature

Temperature is very important when making a 3D print. Without the right temperatures, it is impossible to make a good print. The filament must be melted before it can pass through the nozzle and be printed in layers. The temperature at which the filament transitions from a solid to a liquid form is called the glass transition temperature. This temperature differs per filament: for PLA it is between 60 and 65°C, for PET-G around 70°C and for ABS even between 110 and 115°C. Especially for filaments with a high glass transition temperature, such as ABS, it is crucial to have a high temperature in the printer. This can be achieved by using a heated print bed that heats the print chamber.

Adhesion to the print bed

An additional advantage of a heated print bed is that the first layers of filament on the print bed do not cool down immediately, but stay at the right temperature. This is essential for adhesion. Filament layers adhere well to each other, but not so well to another surface – in this case the glass print bed. This can be solved by setting the correct temperature for each filament. In addition, various aids are available to prevent warping of the print bed. Examples include Kapton tape (adhesion tape) or Dimaxif (adhesion spray). The popular PLA filament can be printed without a heated print bed, but more high-tech filaments like ABS, PP or PC -often used for industrial purposes- cannot be printed without a heated print bed and a closed chamber. The use of adhesion spray or tape is not sufficient, the model will still warp.

High tech filaments

The advantage of filaments with a high glass transition temperature is that as a product they are also resistant to higher temperatures. ABS is therefore often used in the automotive industry for dashboards and bumpers, for example. ABS also has a longer lifespan compared to PLA, as it is less sensitive to weather conditions, for example.

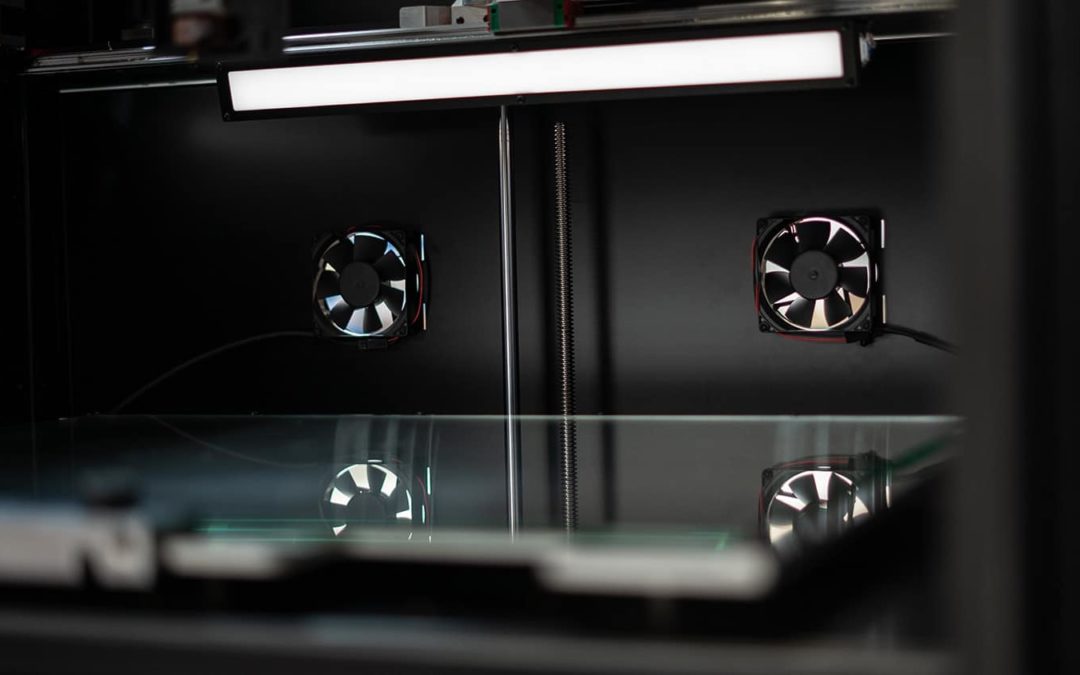

The dddrop RAPID ONE is equipped with a heated print bed and a closed chamber. This enables perfect printing with a wide range of filaments, making the design possibilities endless.

What to do with overheating filament?

A stable printing process

It's all about temperature

Not enough cooling

To high extruder temperature

To be (too) fast

Tip: Perhaps not the most obvious option, but when printing small models you may choose to have multiple models on the board at once. The RAPID ONE has a large volume, which creates a lot of print space on the print bed. By printing multiple models at once, you create more time between depositing the different layers. The extruder head goes to the other models first before the next layer is deposited. This can give just enough time for the layers to cool sufficiently.

The advantage of the dddrop is that all filaments come with ready-made FFF profiles. These are settings that come with the filament. All cooling values are focused on the filament and calculated at room temperature. If the ambient temperature does increase, you can adjust these values at any time with, if necessary, support from our dddrop helpdesk.