Starting with 3D printing

Do you think 3D printing is a (too) big investment for your business? That might be a misconception. 3D printing is becoming more accessible, both in terms of purchase cost and the knowledge required to operate the printer itself. Technologies continue to evolve, and the 3D printer is obviously no exception. The 3D printer is also developing rapidly. There are several affordable, quality plug & play 3D printers on the market, accessible to a wide audience.

Over 25 years ago, we didn’t even know what we could do with a 2D printer, and now we are already in the midst of 3D printer development. The companies or households that do not own a 2D printer, for printing text and images, are probably only a handful. Will the same be true for the 3D printer in 20 years? That’s hard to say, but the fact is that professional 3D printing will no longer be just for large companies by then.

3D printing techniques

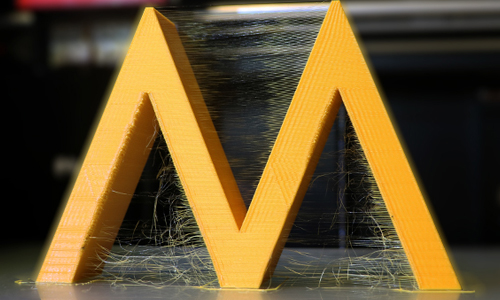

When we talk about 3D printing, we distinguish three main techniques and therefore printer types. In all these techniques, the product is built up from individual layers. The computer ‘reads’ these layers from digital slices of the 3D CAD design. For making functional parts, SLS and FDM are the preferred methods. In addition, SLA printers are available to make products with a very smooth surface, high precision and functional mechanical properties. FDM is the most popular and accessible technique for making products.

The current 3D printer market

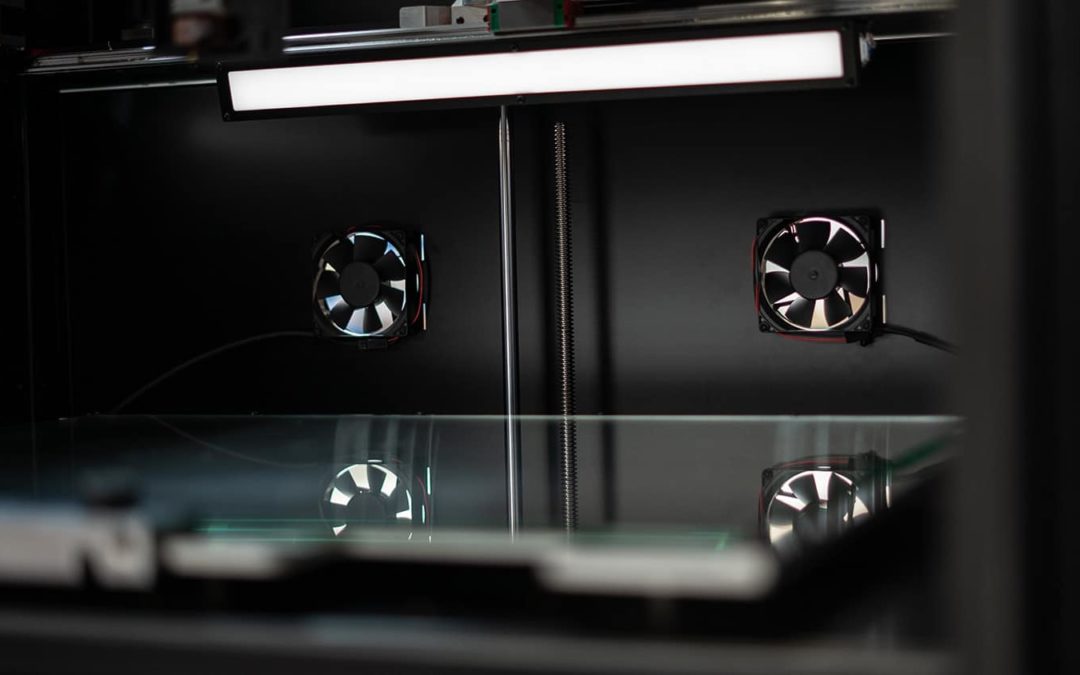

We can divide the current 3D printer market into three segments: the high, mid and low segments (the last being the hobby printer). The hobby printers are available in various webshops, with prices ranging from €250 to €3000. These printers generally do not have a closed housing and are therefore very sensitive to the environment. Nice for home use, but when the product is intended for prototyping or small series, it is advisable to switch to a printer from the middle or high segment.

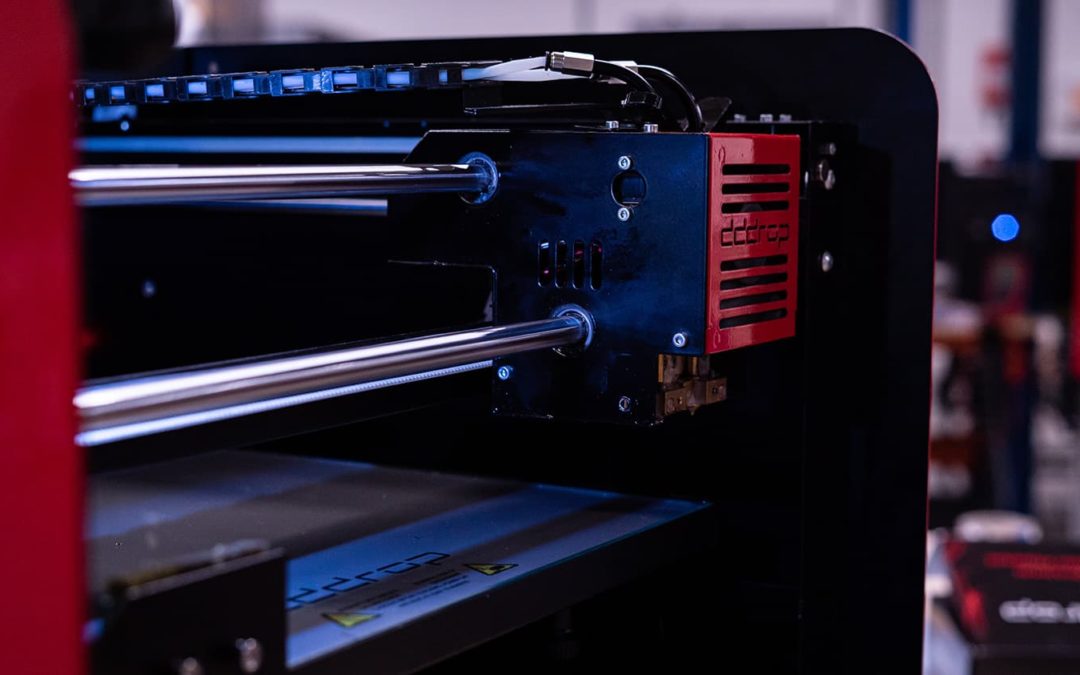

The mid-range printers are priced between €4000 and €20,000. These printers are well-developed machines with many features, yet are easy to use. The included software automatically converts your 3D models to printable files. Especially the printers with a closed housing and an open filament system can be used for numerous applications. Finally, there are the high-end printers. This includes the printers with prices above €20,000, which is a large investment. It is therefore important to determine what the printer can do for your business and how much it will actually be used.

Is 3D printing worth the investment?

You may fantasize about owning a 3D printer, but the question remains whether it is worth the investment. A 3D printer is especially beneficial in three parts of the development and production process; in prototyping, in producing small batches, and in creating “new” shapes that are not feasible with traditional techniques.

3D print prototyping

More and more companies discover 3D printing as a useful tool for making prototypes. The biggest gain is time. You no longer lose weeks on making scale models or waiting for an externally produced product. With your own 3D printer you can start the print when you leave in the evening and the next day your scale model or product is finished.

Producing small series with a 3D printer

The current, traditional, production methods are mill-turn and injection molding techniques. For small batches, these techniques are very expensive. When you for instance only need 50 pieces of a certain part, it is much cheaper to print these yourself. Moreover, you have very little risk of stocks. You just turn on your printer and there the parts are.

Printing ‘new’ shapes

Traditional manufacturing techniques are limited in making certain shapes. Hollow products, for example, are fine to produce with a 3D printer. This means that your designers have fewer limitations in the development and production process.

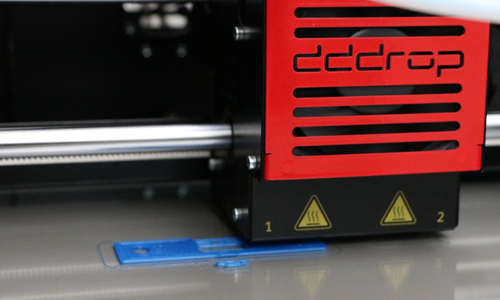

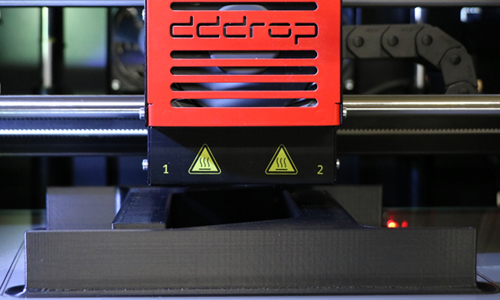

Curious what a 3D printer can do for your company, without a too big investment? Have a look at our dddrop RAPID ONE or contact us for an informal consultation: info@dddrop.com.

Increase infill percentage

Increase infill percentage