In-house 3D printing or outsourcing: which option is best for you?

3D printing is becoming more and more popular, and businesses everywhere are trying to figure out if they should invest in their own 3D printers or outsource their printing needs. This decision can really affect how your company operates, spends money, and innovates. Let’s dive into the pros and cons of in-house 3D printing versus outsourcing, so you can decide what’s best for you.

1. Cost considerations

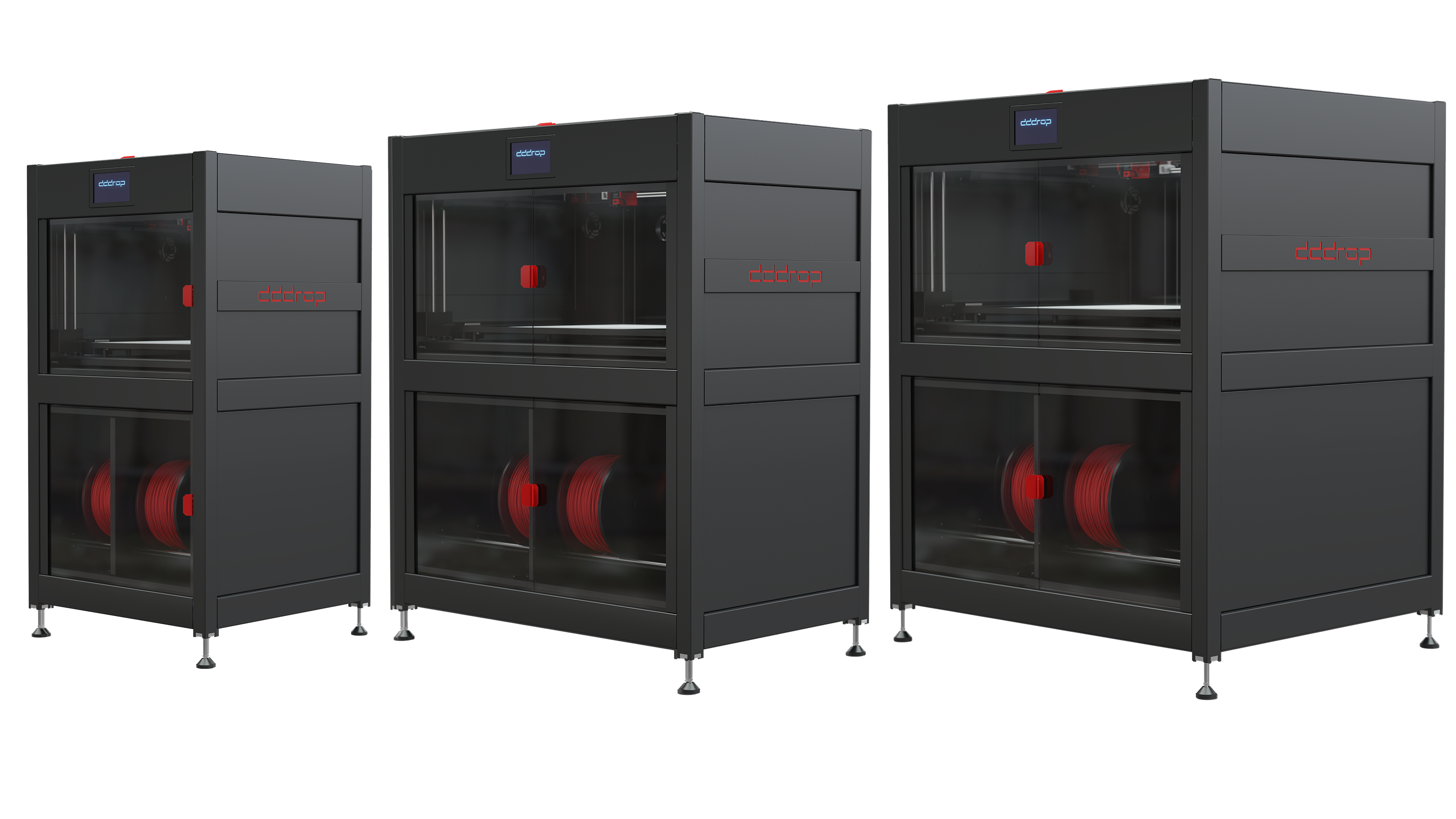

Initial Investment: Buying your own 3D printer can be expensive. High-quality, large-format 3D printers can cost anywhere from $10,000 to $100,000 or more. Plus, there are ongoing expenses for maintenance, materials, and training. On average, you might spend about 10% of the printer’s price on annual maintenance.

Operational Costs: After you buy the printer, printing in-house often is cheaper per unit, especially if you print a lot. Outsourcing, however, means you don’t have to spend a lot of money upfront. Service providers charge based on how complex, big, and numerous your prints are. If you only need to print occasionally or in small quantities, outsourcing might save you money.

2. Speed and turnaround time

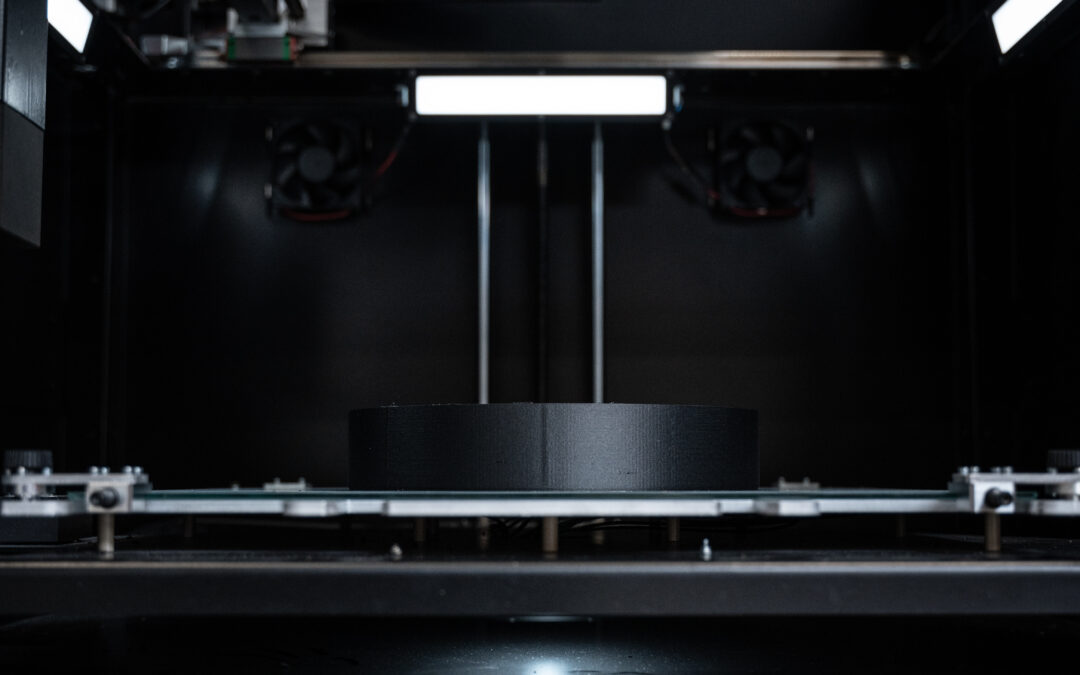

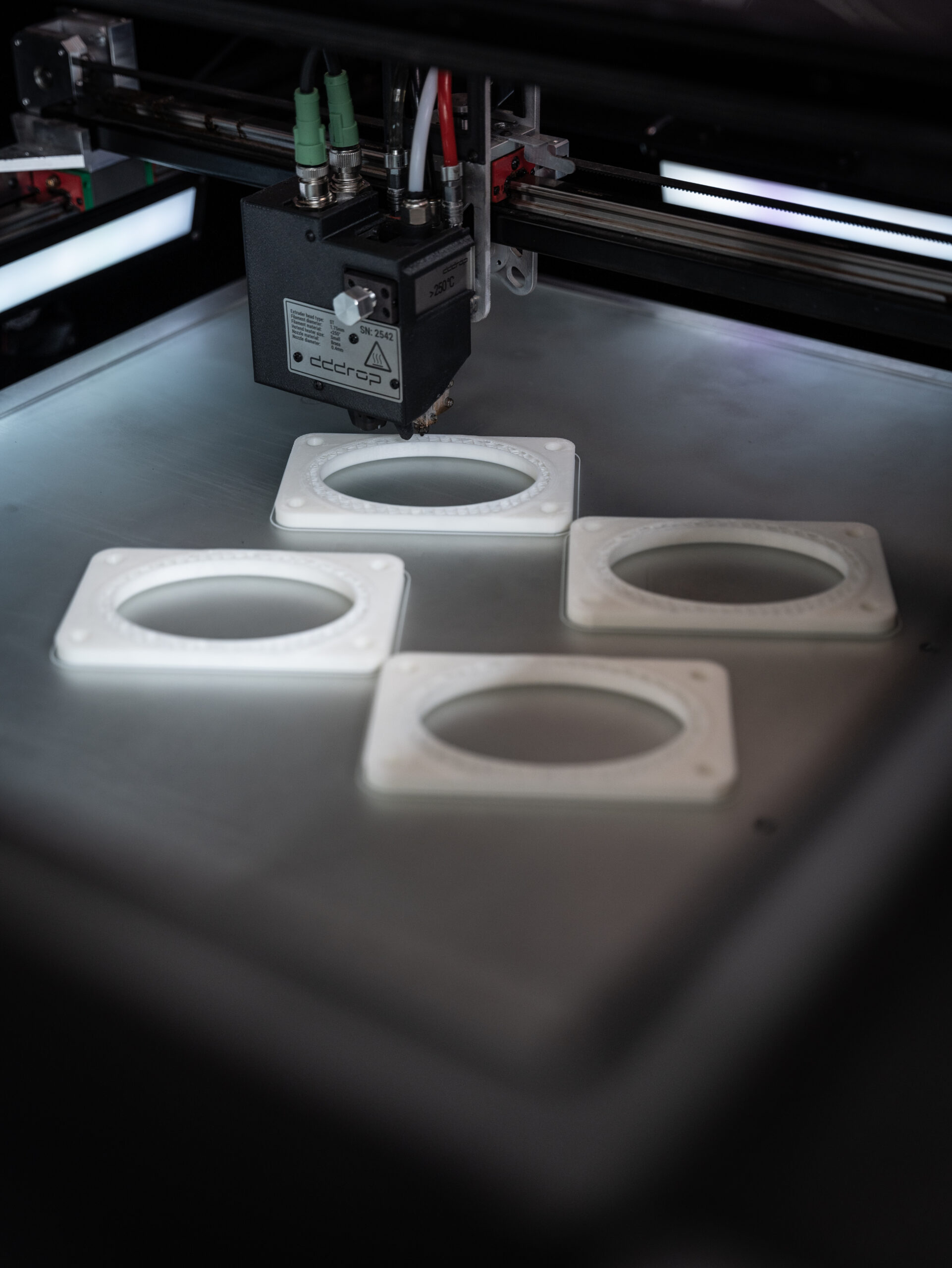

In-House Printing: Having a 3D printer on-site means you can print prototypes and parts quickly. This speed is crucial if getting products to market fast is important for your business. Some companies have cut their product development time by up to 50% with quick in-house prototyping.

Outsourcing: While outsourced services often have advanced equipment and expertise, shipping and handling can slow things down. Depending on the provider and your location, it could take anywhere from a few days to several weeks to get your parts.

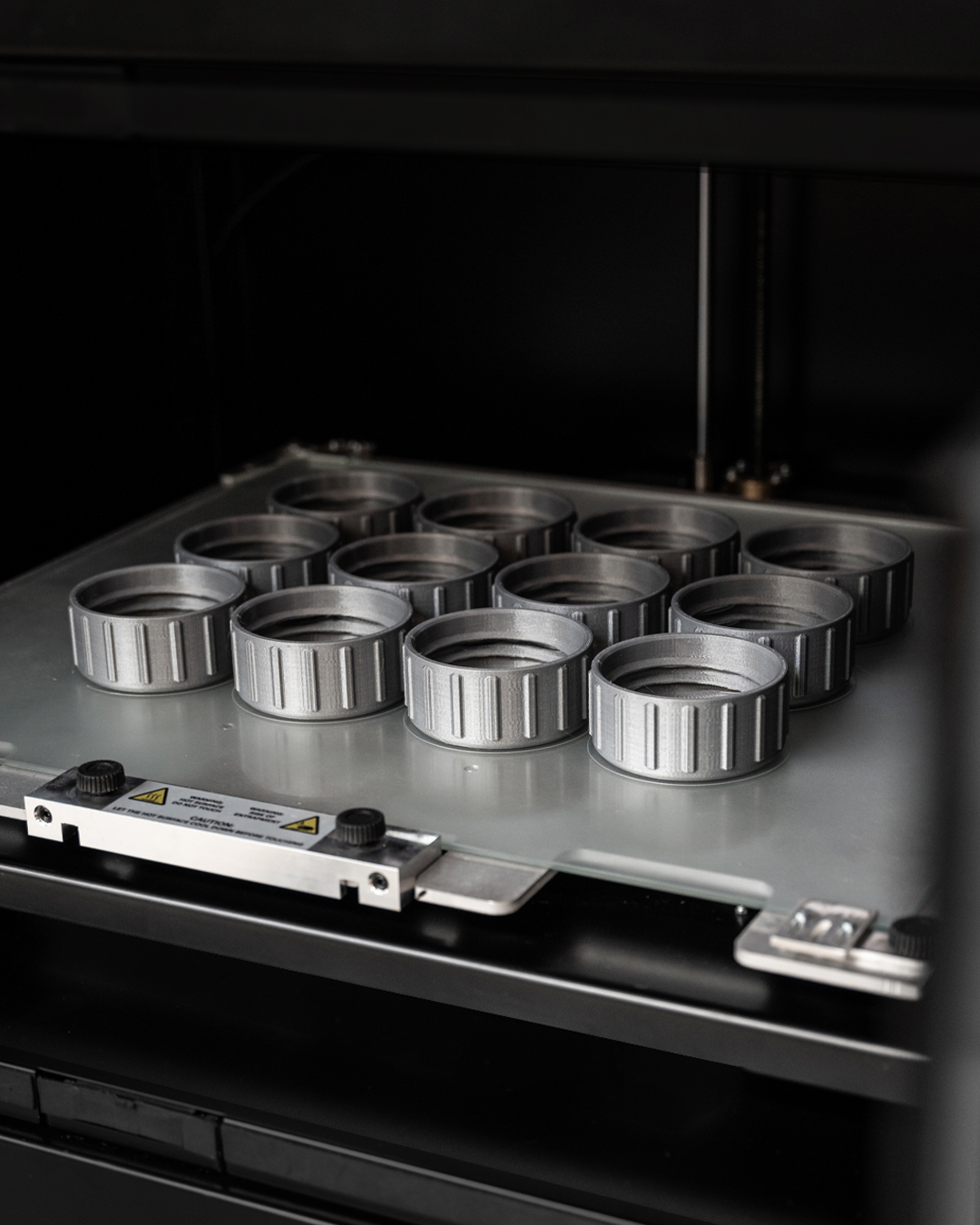

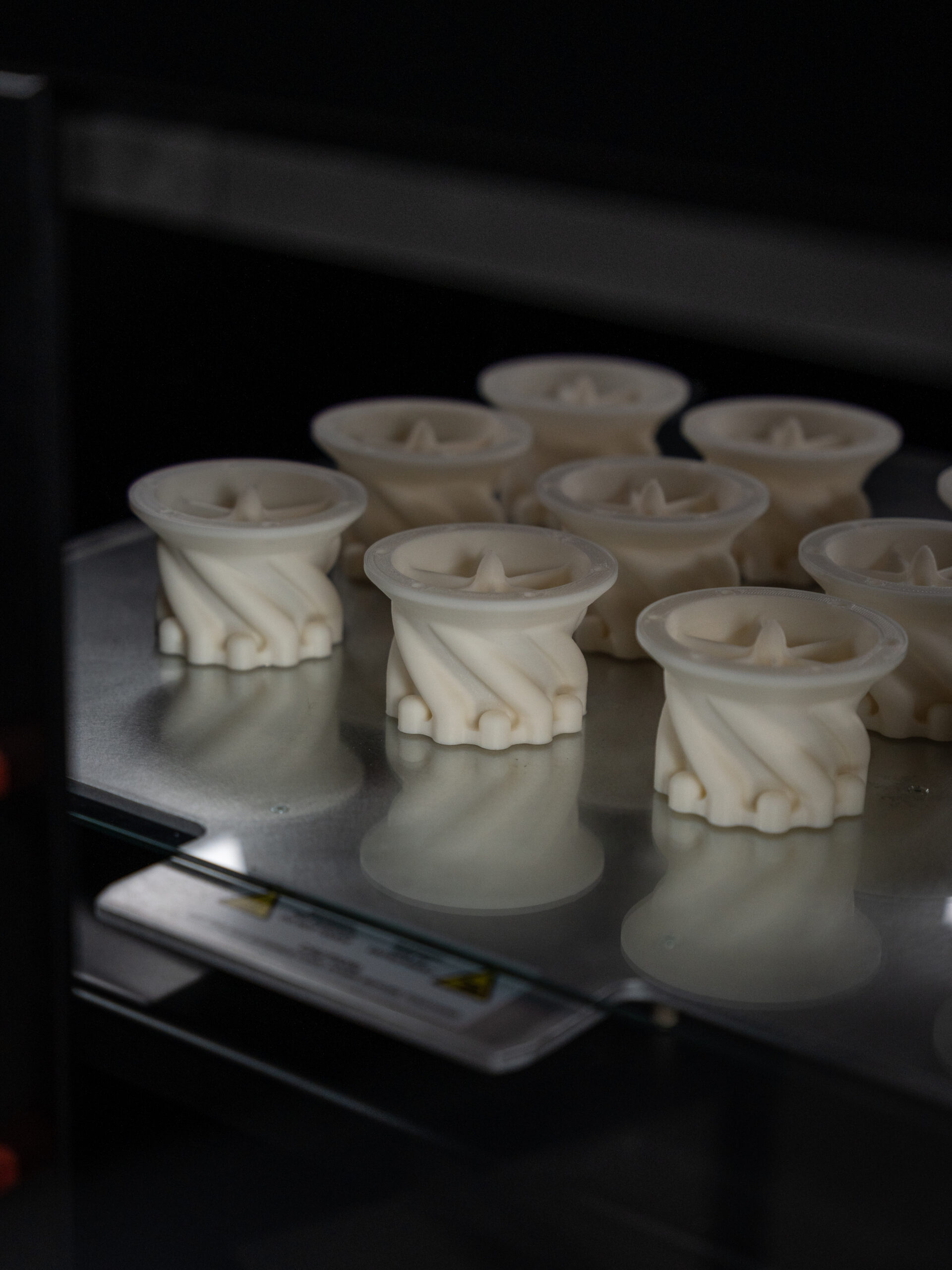

3. Flexibility and control

In-House Printing: Owning your own 3D printer gives you complete control over the printing process. You can experiment with different materials, designs, and techniques whenever you want, without waiting on an external schedule. This flexibility can lead to more innovation and faster iterations.

Outsourcing: Outsourcing allows you to scale up or down based on your project needs without worrying about equipment limitations. However, you might have less control over the process and quality, as you’re dependent on the service provider’s standards and practices.

4. Confidentiality and intellectual property

In-House Printing: Printing prototypes and parts in-house minimizes the risk of intellectual property theft or confidentiality breaches. Sensitive designs and proprietary information stay within your company’s secure environment.

Outsourcing: When you outsource, you have to share your designs with third parties, which can pose risks to your intellectual property. Make sure the service provider has strict confidentiality agreements and secure processes.

Conclusion: making the right choice

Deciding between in-house 3D printing and outsourcing depends on your specific business needs, budget, and long-term goals. Here are a few questions to help guide your decision:

- How often do you need 3D printed parts?

- What’s your budget for initial investment and ongoing costs?

- How critical is turnaround time for your projects?

- How important is confidentiality and control over the printing process?

Ultimately, the choice between in-house 3D printing and outsourcing is a strategic decision that can drive innovation and efficiency in your operations. By carefully evaluating your needs and resources, you can make an informed decision that aligns with your business goals.