In the exciting world of industrial 3D printing, the technology has made significant advances and the possibilities have grown exponentially in roughly 10 years. One of the key developments that is attracting attention is the emergence of large print volumes in industrial 3D printers. This innovation has the potential to dramatically change the way we produce and manufacture. In this article, we take a closer look at 5 benefits of large print volumes in industrial 3D printing.

1. Increase in scale and efficiency

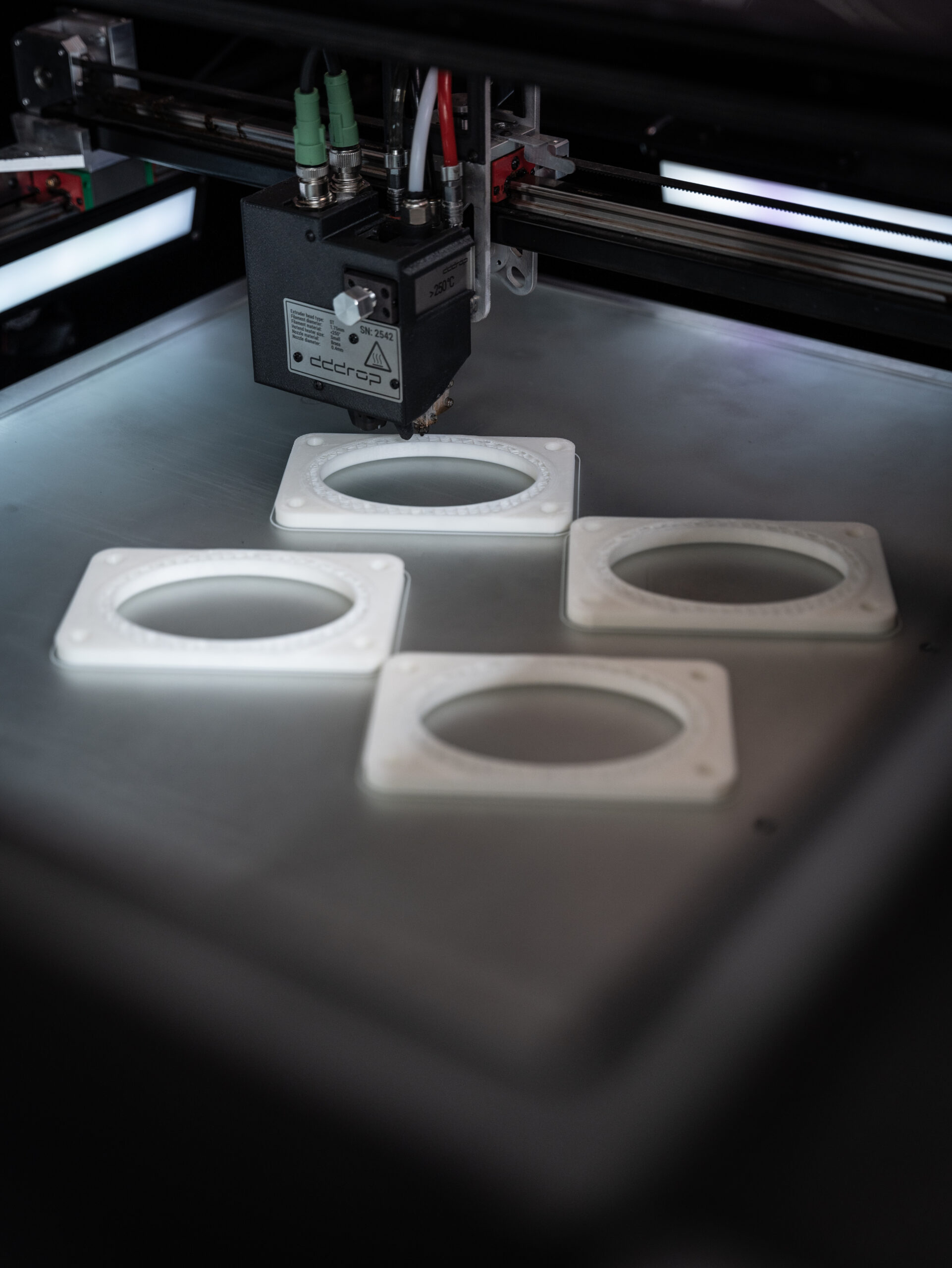

One of the most obvious advantages of large print volumes is the ability to print larger objects at one time. This offers significant advantages for industrial manufacturing, where efficiently producing large numbers of parts is crucial. With a larger print volume, manufacturers can produce larger components or multiple smaller parts simultaneously, shortening the production cycle and increasing overall efficiency.

2. Complex designs and prototyping

Large print volumes in industrial 3D printers open the door to creating complex and detailed designs that were previously impossible to achieve. This is especially valuable for prototyping, where engineers and designers can experiment with innovative designs without worrying about print volume limitations. This results in faster iterations and shorter time-to-market for new products.

3. Less assembly and material waste

Large print volumes allow manufacturers to print larger parts that might otherwise consist of multiple smaller parts. This leads to a reduction in assembly time because fewer parts need to be assembled manually. It also minimizes the need for intermediate joints or fasteners, resulting in a stronger end product. This ultimately provides a reduction in material and lowers labor costs.

4. Cost savings at scale

Although the initial investment in an industrial 3D printer with a large print volume can be significant, it can lead to significant cost savings in the long run. The ability to print larger parts or multiple parts simultaneously reduces the need for expensive mold manufacturing or CNC machining. This allows companies to streamline their manufacturing processes and save costs on both labor and materials.

5. Diversification of applications

Another advantage of large print volumes is the ability to address a wider range of applications. From large-scale prototyping and industrial components to custom production and even art and architecture. The possibilities are endless. This diversification allows companies to tap new markets and adapt to changing customer needs.

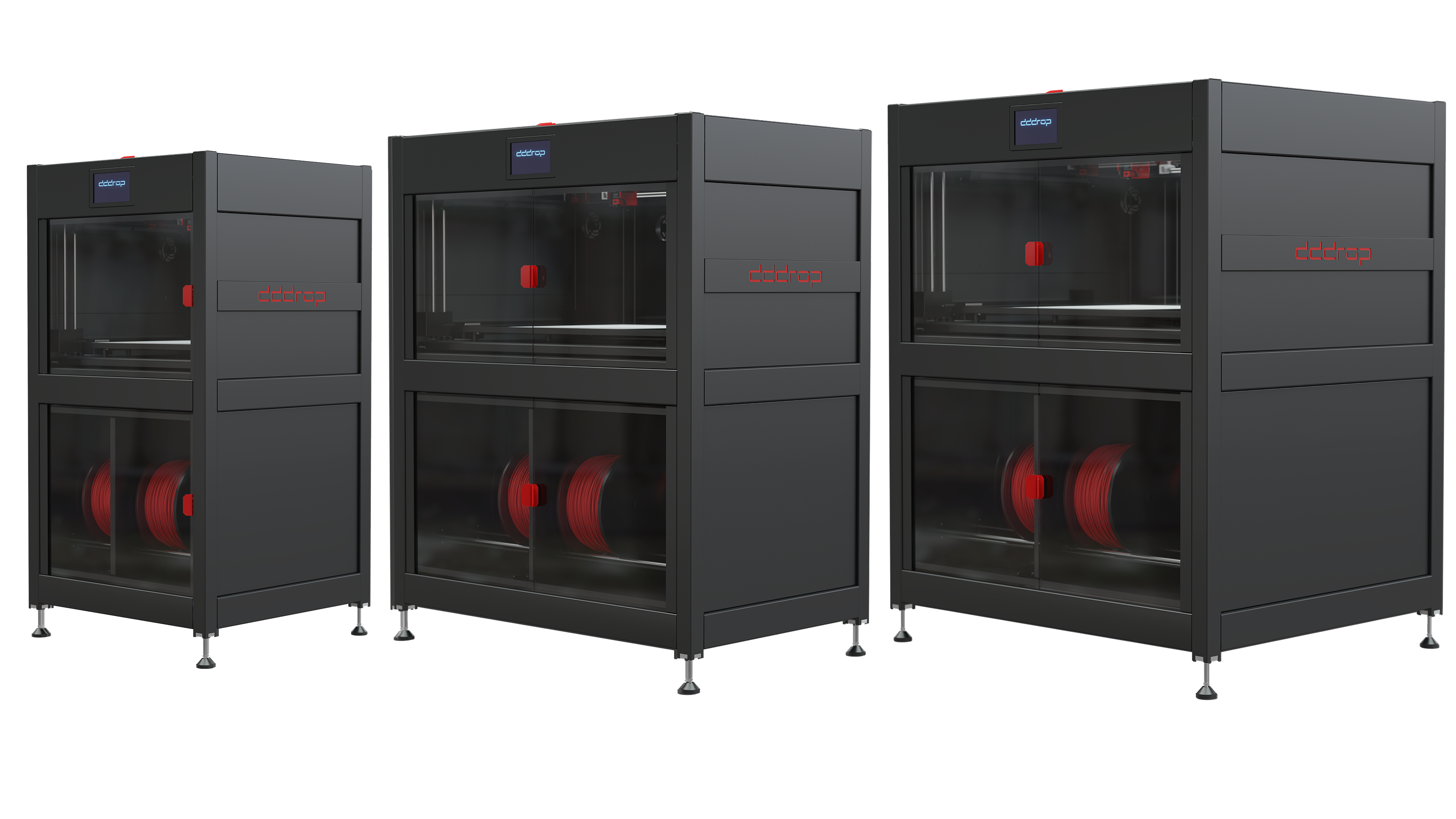

dddrop Rapid One’s scalable frame

The emergence of large print volumes in industrial 3D printing opens new doors for efficiency, complex designs, cost savings and diversification of applications. This technological development has the potential to transform the manufacturing industry and drive innovation on multiple levels.

The dddrop Rapid One is the first industrial 3D printer with a scalable print volume. Are you looking for a printer for large prints, a large batch of parts or complex prints? Request a free quote or contact us for more information!