PLA Filament

PLA Filament is made from reusable sources, namely starchy plants such as corn plants, sugar beets or sugar cane. This makes PLA a thermoplastic. It is a lot more environmentally friendly than, for example, ABS filament, which is manufactured from fossil fuels.

Properties

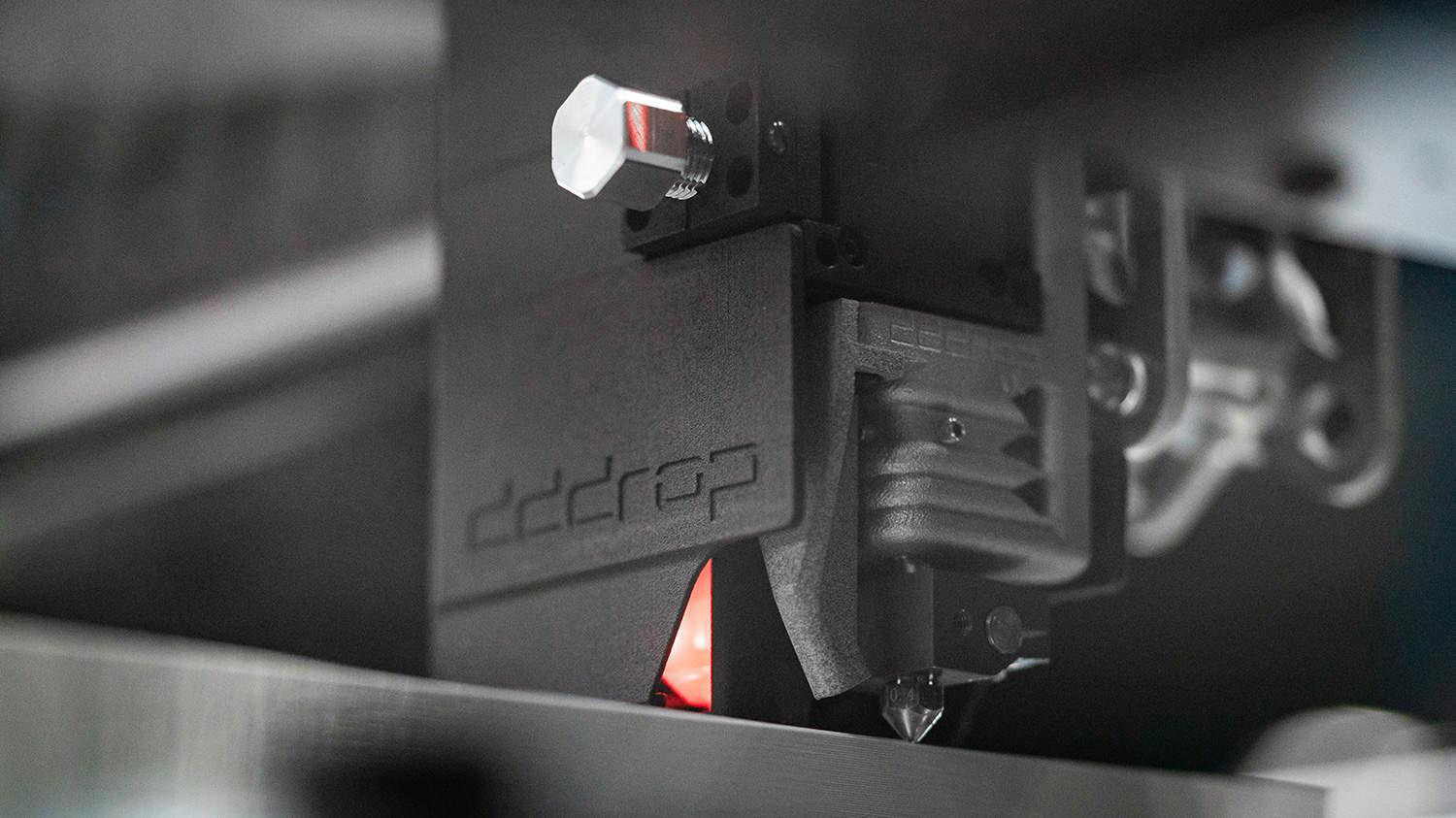

PLA is highly popular, because of the combination of ease of use, material strength and model accuracy. The greatest advantage of this material is that it can be printed using lower temperatures compared to other material options, and no heated print bed is required.

Applications

PLA is known for being a strong and stiff, nonflexible material. Finished PLA prints are visually appealing and very accurate to the model source. In addition, PLA is a low-cost material that makes it suitable for prototyping, experimenting and testing.

PLA is used for accurate test and calibration models as well as visual models. It is not suitable for industrial use but it is perfect for prototypes and visual models due to its dimension accuracy, low cost, and biodegradability.

The advantages of PLA filament

- Leaves no unpleasant smell

- Easy to shape

- Does not wrap

- No heated printbed required

- Adheres easily to various surfaces

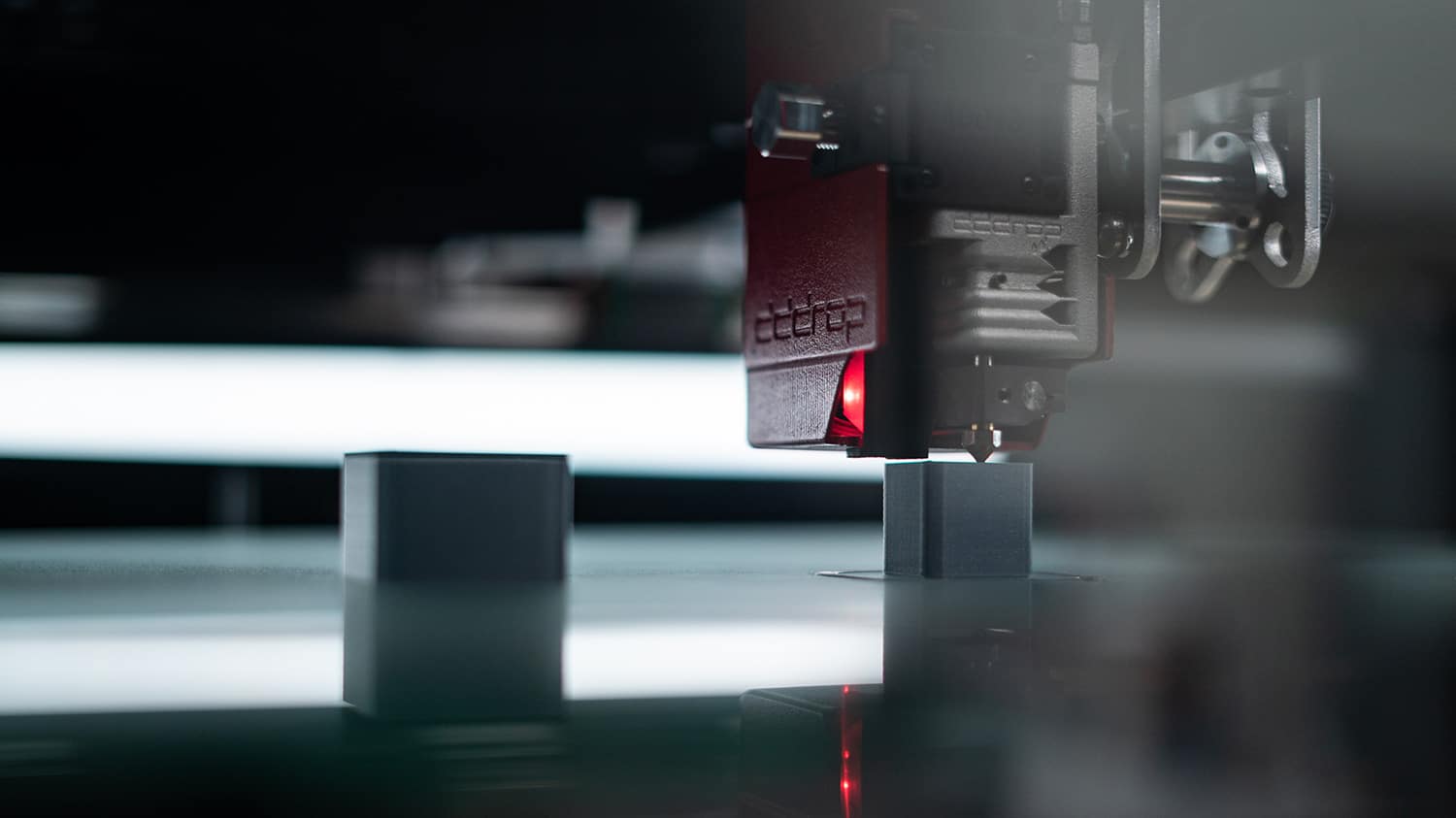

The easiest 3D printing material

Among all the different raw materials for 3D printing, PLA filament is the most widely used material in the world. As such, this filament is used by all kinds of different organizations, from small to large. We recommend consumers and companies who are starting 3D printing for the first time to start with this material. PLA is easy to use and in addition, this material does not contain any harmful substances. So users can basically take their first steps in 3D printing without any worries.

Specificaties

| Diameter: | 1.75 mm |

| Weight: | 1 kg |

| Print temperature: | 220-240°C |

| Melt temperature: | 277-146˚C |

| Print bed temperature: | ±60˚C |

| Storage: | Cool & dry (15-25°C), away from UV light. |

| Note: | The values shown are an indication and could differ between different printers. Please refer to our support page for more information |

- Strength 66%

- Flexibility 34%

- Stiffness 79%

- Print Temperature 18%

- Ease of Use 90%