PET-GFilament

Properties

PET-G is a strong and durable material that is also resistant to water and chemicals. While printing with the PET-G filament, few if any problems occur with regard to shrinkage or warping. This filament is resistant to fatigue and repeated use.

To make PET-G, a second glycol is added during polymerization. This offers a significant advantage over PET plastic. When PET is heated multiple times, it becomes fuzzy and brittle. With the glycol modification of PET-G, this is no longer an issue.

Applications

PETG is the only filament approved for use in food contact (provided the machine and equipment have not been used with other 3D printing materials) making it excellent for use in many industries. In addition, the combination of strength, toughness, and flexibility makes PET-G ideally suited for parts that move a lot and where material fatigue often occurs. PET-G is also well suited for water-resistant applications and parts that “snap” into place.

The advantages of PET-G filament

- Easy to print material

- Excellent layer adhesion

- High durability

- PET-G filament does not crystalize

- Strong material

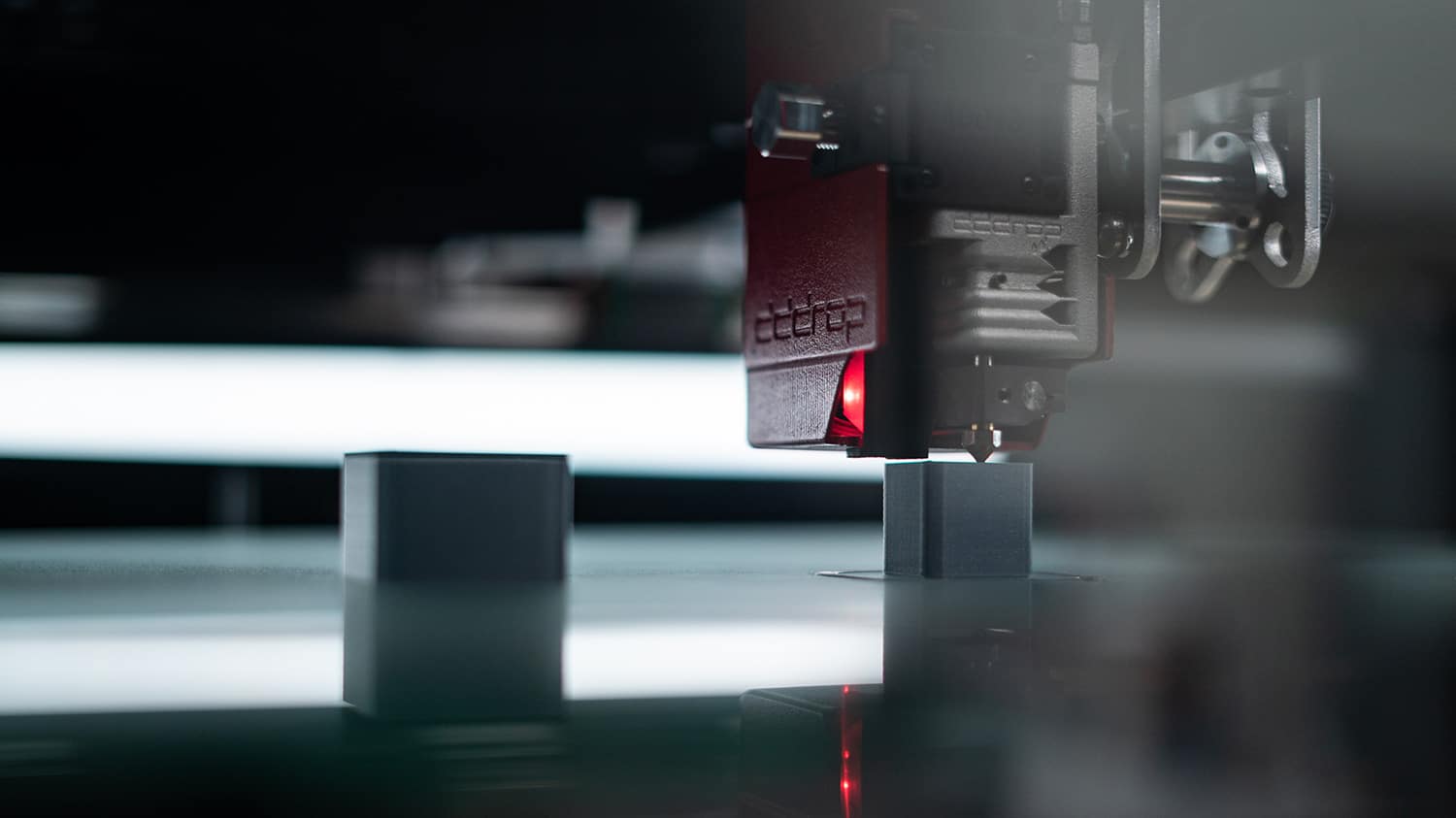

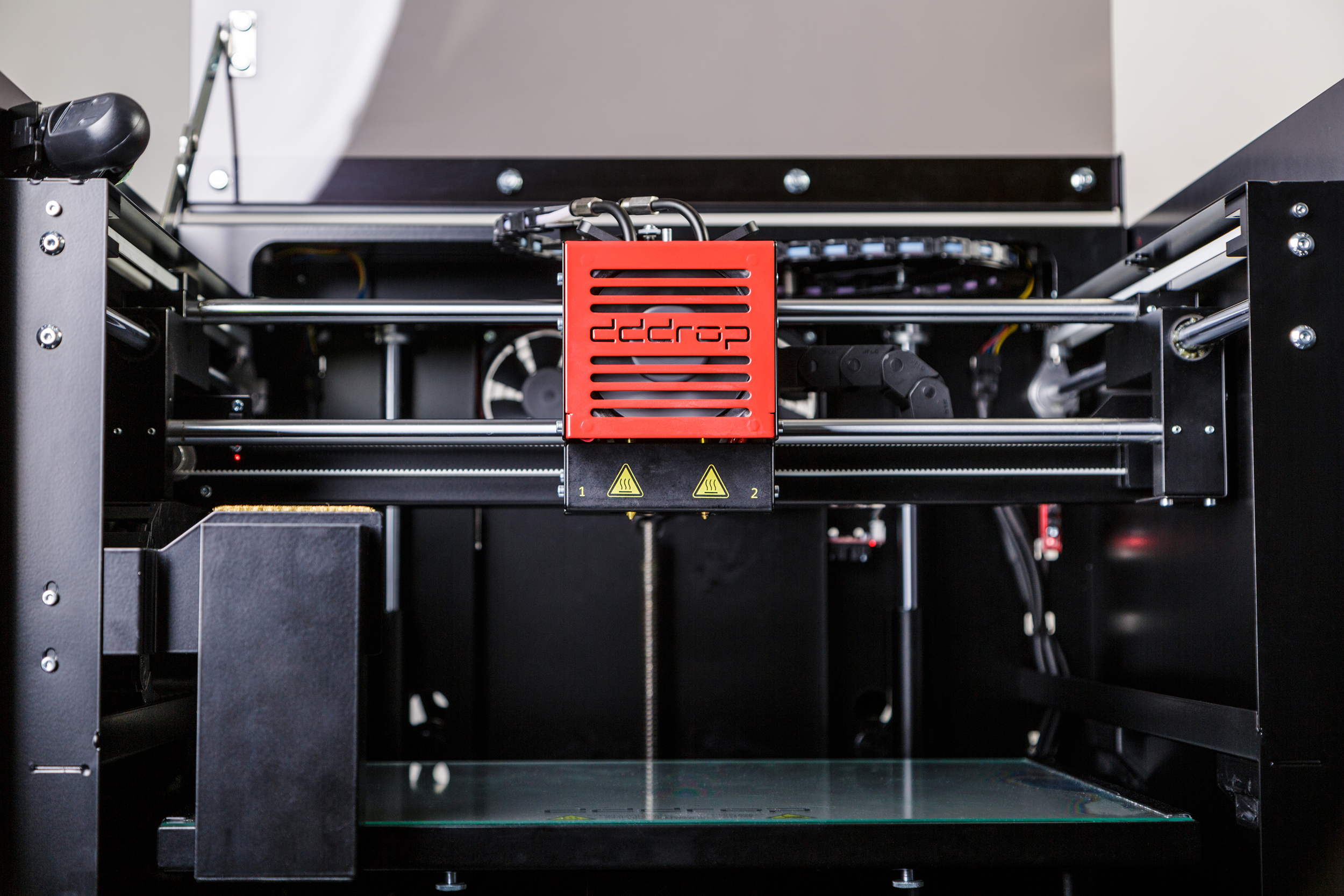

The best way to print with PET-G filament

To get the best out of your PETG print there are a number of things you need to take into account. First of all use the right temperature. Because PETG has a high melting point, the extruder must be between 210 and 250 degrees Celsius. In addition, the platform should be set between 80 and 100 degrees Celsius. Speed is also important. The most ideal speed for PETG filament is between 60 and 100 mm per second. 3D printing at a higher speed may result in lower quality.

Specifications

| Diameter: | 1.75 mm |

| Weight: | 1 kg |

| Print temperature: | 230-250°C |

| Melt temperature: | 77-146°C |

| Print bed temperature: | 75˚C |

| Storage: | Cool & dry (15-25°C), away from UV light. |

| Note: | The values shown are an indication and could differ between different printers. Please refer to our support page for more information |

- Strength 66%

- Flexibility 34%

- Stiffness 79%

- Print Temperature 18%

- Ease of Use 90%