PA CARBON Filament

Applications

PA Carbon is an ideal solution for any application which requires light weight and rigidity. Reinforcing parts with carbon fiber, reducing the use of material and weight, is extremely popular. PA carbon filament is characterized by a high chemical resistance to aromatic hydrocarbons, greases, oils, halogenated hydrocarbons and is therefore widely used in aerospace, civil engineering, military and motorsport.

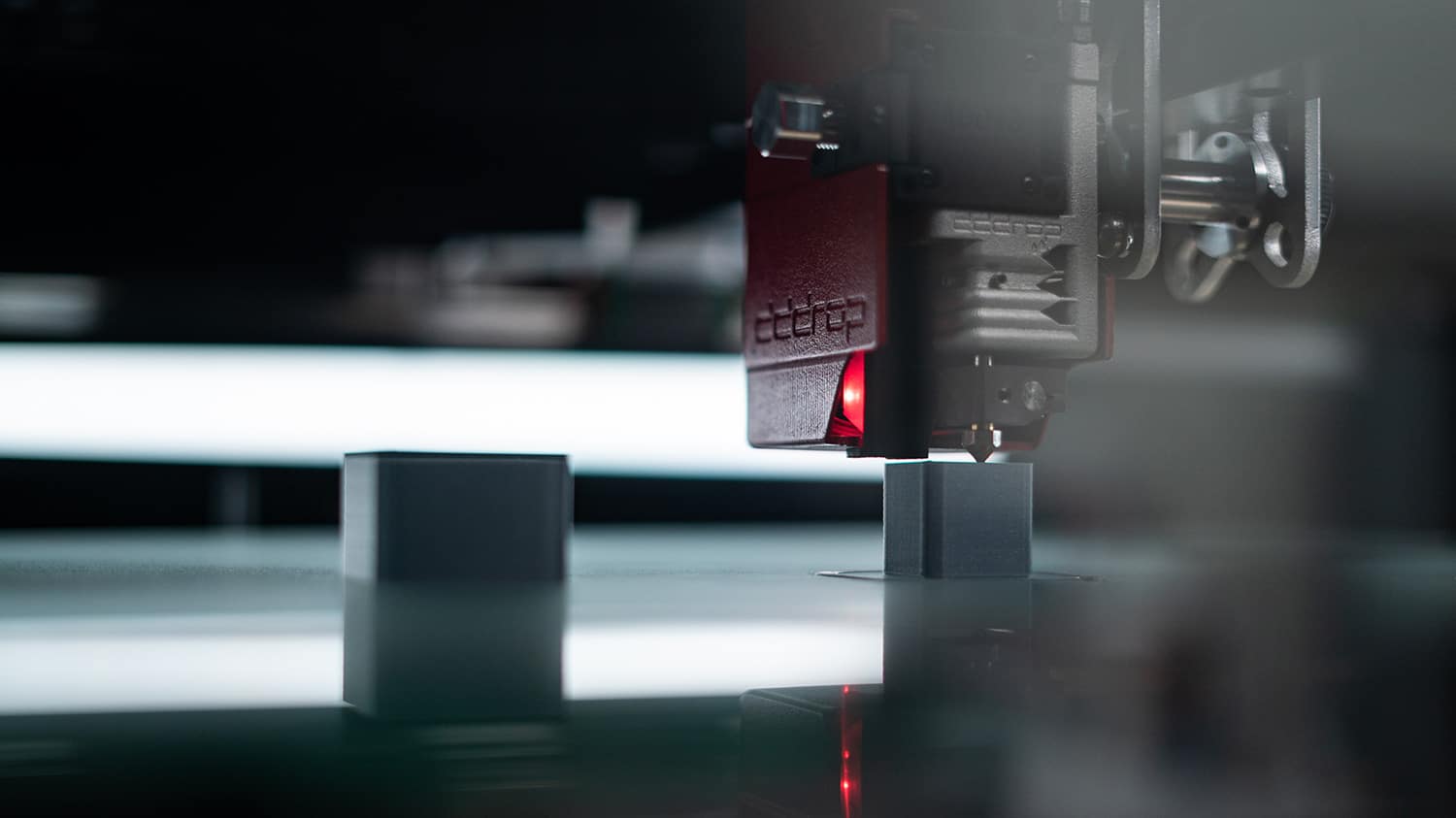

Filament dryer for perfect quality

PA Carbon is nylon based filament like PA-12. So, it is made using nylon and will absorb more moisture than other filaments when left exposed to the environment. Excessive moisture will result in popping at the nozzle (water boiling off, a little steam) and excessive drooling and nozzle build-up. Fortunately, the dddrop rapid one has a built-in filament dryer that ensures the filament remains of the right quality.

The advantages of PA Carbon filament

- High strength and lightweight

- Corrosion resistance

- Stress resistance

- Thermal friendly

Specifications

| Diameter: | 1.75 mm |

| Weight: | 0.5 kg |

| Print temperature: | 285°C |

| Melt temperature: | 200°C ± 10˚C |

| Print bed temperature: | ±85˚C |

| Storage: | Cool & dry (15-25°C), away from UV light. |

| Note: | The values shown are an indication and could differ between different printers. Please refer to our support page for more information |

- Strength 100%

- Flexibility 20%

- Stiffness 80%

- Print Temperature 100%

- Ease of Use 20%