ABS Filament

ABS is a strong and stiff filament that is low-cost, easy to use and great for durable parts.

Properties

ABS is a strong and tough material that is resistant to heat and impact. ABS is non-flexible and can withstand high pressures which makes it great for industrial applications.

Applications

The most well known ABS product is the LEGO plastic block. However, ABS is ideal for industrial use thanks to its ability to withstand high temperatures. It is durable and reliable so it can be implemented in end-products. Some of the many implementations are in the automotive industry where ABS is used to construct dashboards, bumpers and other automotive hardware.

The advantages of ABS filament

- Durable, hard and rigit material

- Prints at high speed

- High impact strength

- Mechanical properties

- Good chemical resistance

ABS Composition

ABS is made from petroleum products so printing with ABS is best done in a ventilated room. ABS is composed of a blend of acrylonitrile, butadiene, and styrene. The first provides heat and chemical resistance, the second provides impact resistance and strength, and the last provides ABS with a low layer visibility for a smoother finish.

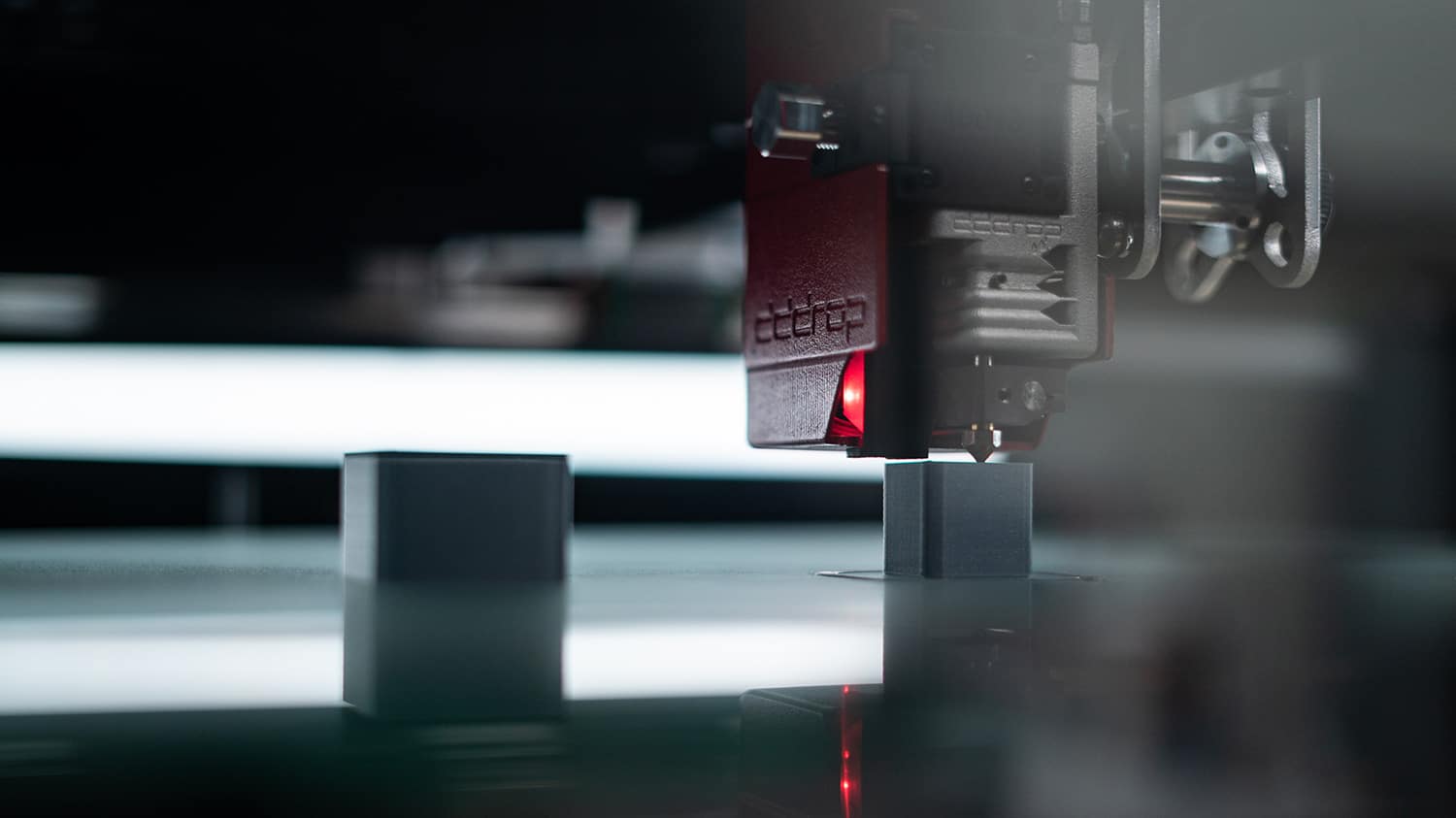

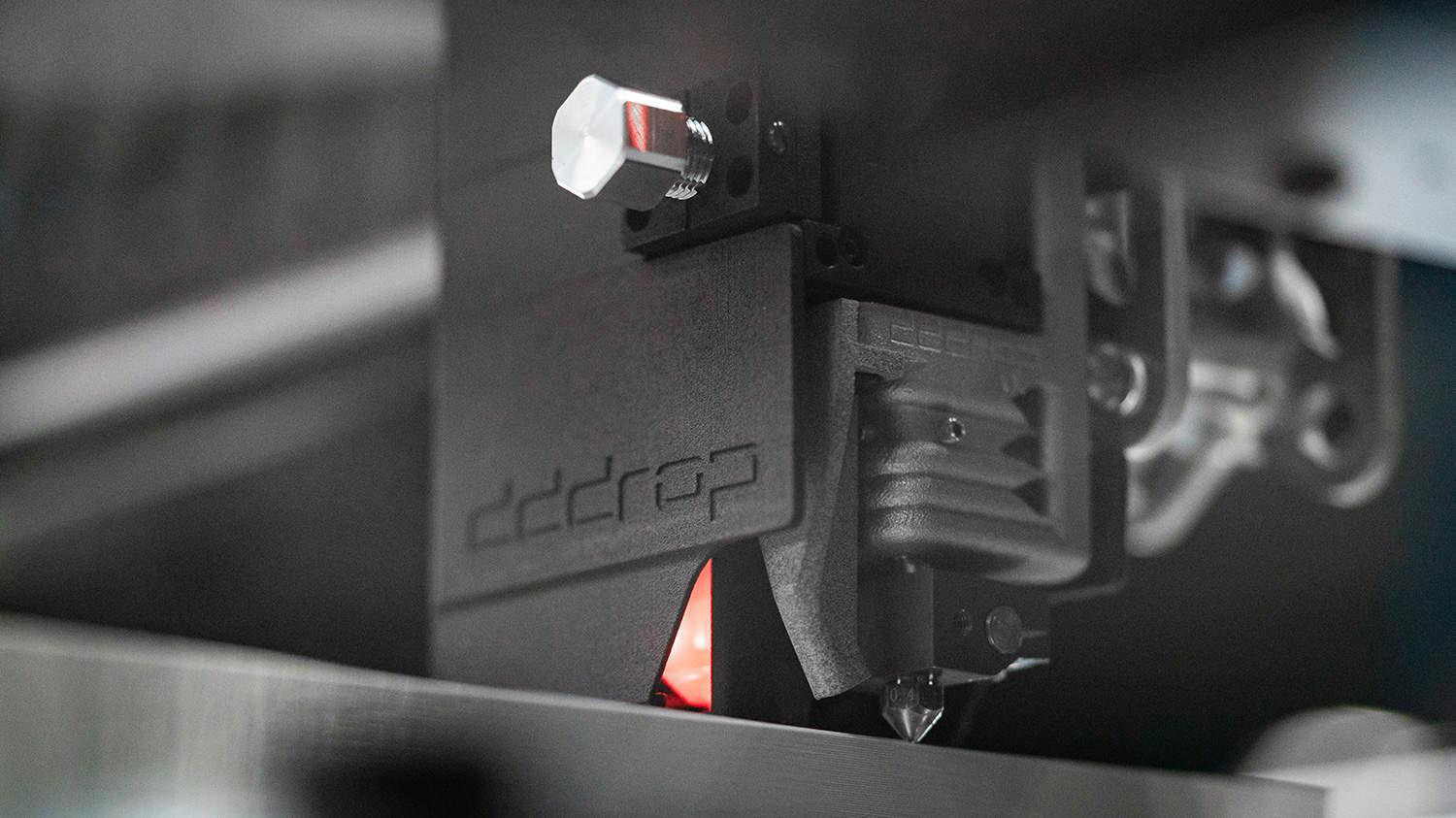

Ensure good ventilation during 3D Printing

During printing of ABS filament a strong odor is released, which many people find unpleasant. Therefore, it is wise to print ABS with good ventilation. The average temperature at which ABS can be printed is 225 to 250 degrees Celsius.

Specifications

| Diameter: | 1.75 mm |

| Weight: | 1 kg |

| Print temperature: | 220-240°C |

| Melt temperature: | 277-146˚C |

| Print bed temperature: | ±60˚C |

| Storage: | Cool & dry (15-25°C), away from UV light. |

| Note: | The values shown are an indication and could differ between different printers. Please refer to our support page for more information |

- Strength 66%

- Flexibility 34%

- Stiffness 79%

- Print Temperature 18%

- Ease of Use 90%