How thin can a 3D printer print?

Explore the limits of 3D printing technology as we delve into the question: how thin can a 3D printer print? This guide unfolds the intricacies of achieving fine prints, shedding light on nozzle sizes, wall thickness, and the tweaks that can make all the difference.

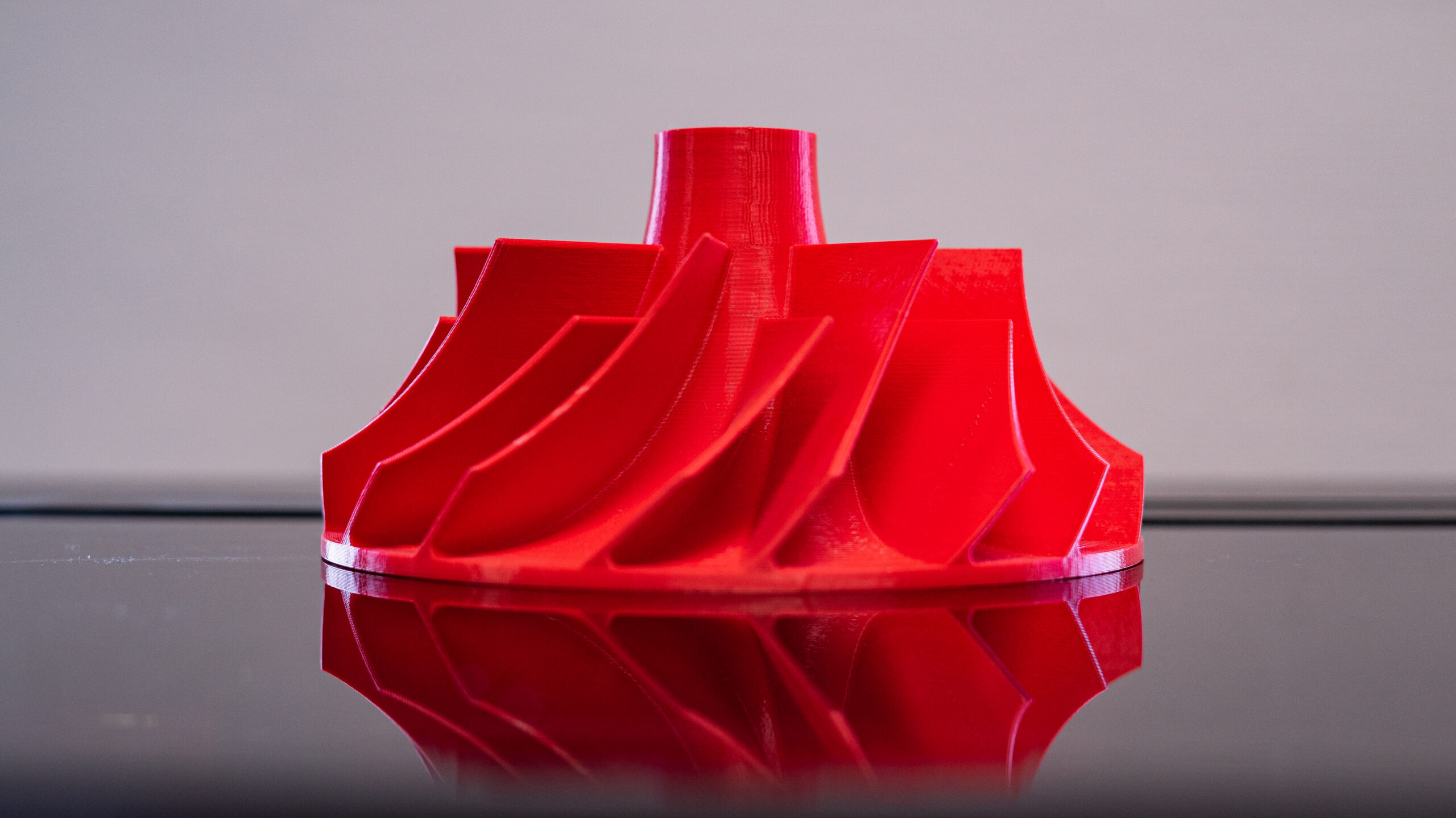

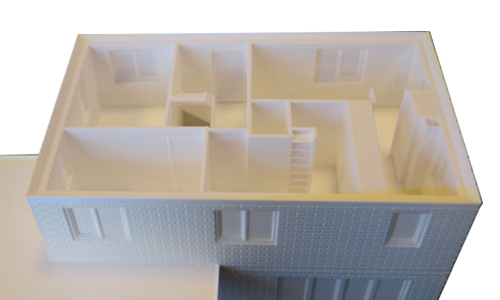

With FDM printing, a model is constructed by printing layers of filament (plastic). This filament is heated until it melts and is then guided through the nozzle of the printer. The width of the layer that is printed onto the print bed is partly determined by the size of the nozzle. Several sizes are available, to enable printing different wall thicknesses (extrusion widths). When printing thin-walled models, it’s good to know how this exactly works. When the wrong settings are used, it could happen that a wall isn’t constructed correctly or not even printed at all. This often happens when models are scaled down.

Different nozzle sizes

The various nozzle sizes can be used for different purposes. Do you want a model to be printed quickly, without paying too much attention to the details? Then choose a big nozzle size like 1.0mm. This nozzle prints a wide and high layer, resulting in less required layers and therefore a quicker result. However, if you want to print a detailed or thin-walled model, you should choose a smaller nozzle, like 0.2 or 0.4mm.

Too thin walls

Change the design

Change the nozzle

Material considerations for thin printing

Software settings for optimized thin printing

Common challenges and solutions in thin printing

Conclusion

FAQ

How thin is too thin for a 3D printer?

The minimum thickness a 3D printer can achieve is determined by its hardware, particularly the nozzle size. For a standard 0.4 mm nozzle, the thinnest line it can technically print is 0.24 mm, which is achieved by adjusting the line width parameter in the slicing software. There are experimental settings in some slicing software like Cura that might allow for printing thinner walls, but they come with their own set of challenges.

What is the thinnest layer a 3D printer can print?

The thinnest layer height, or Z resolution, is typically around 0.025 mm or 25 microns for SLA 3D printers, and around 0.1 mm or 100 microns for FDM 3D printers.

Is 0.2 mm good for 3D printing?

A 0.2 mm layer height is a common setting for FDM 3D printers when a balance between detail and printing time is desired. It provides a good level of detail while not being as time-consuming as finer layer heights like 0.1 mm.

What is the minimum line thickness for 3D printing?

The minimum line thickness for 3D printing is often equated to the nozzle diameter of the 3D printer. For instance, with a 0.4 mm nozzle, a minimum line width of 0.24 mm is achievable.