What role can 3D printing play in prototyping?

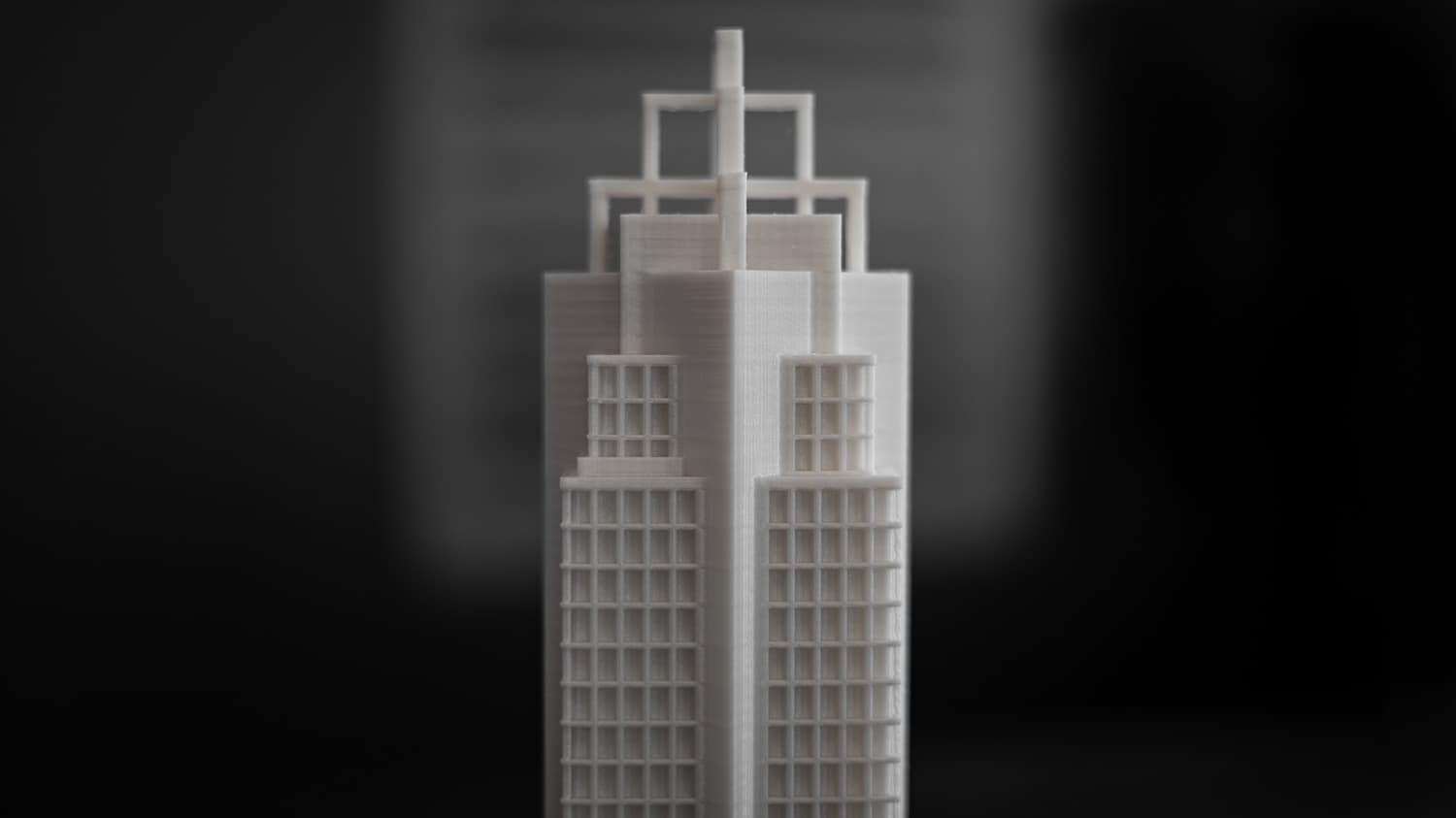

Prototyping and design testing are consistent processes of product development. These allow designers to interact and examine their creation thoroughly before assembling and producing the final iteration. 3D printing makes prototyping and product development a much quicker and easier process.

Why 3D printing?

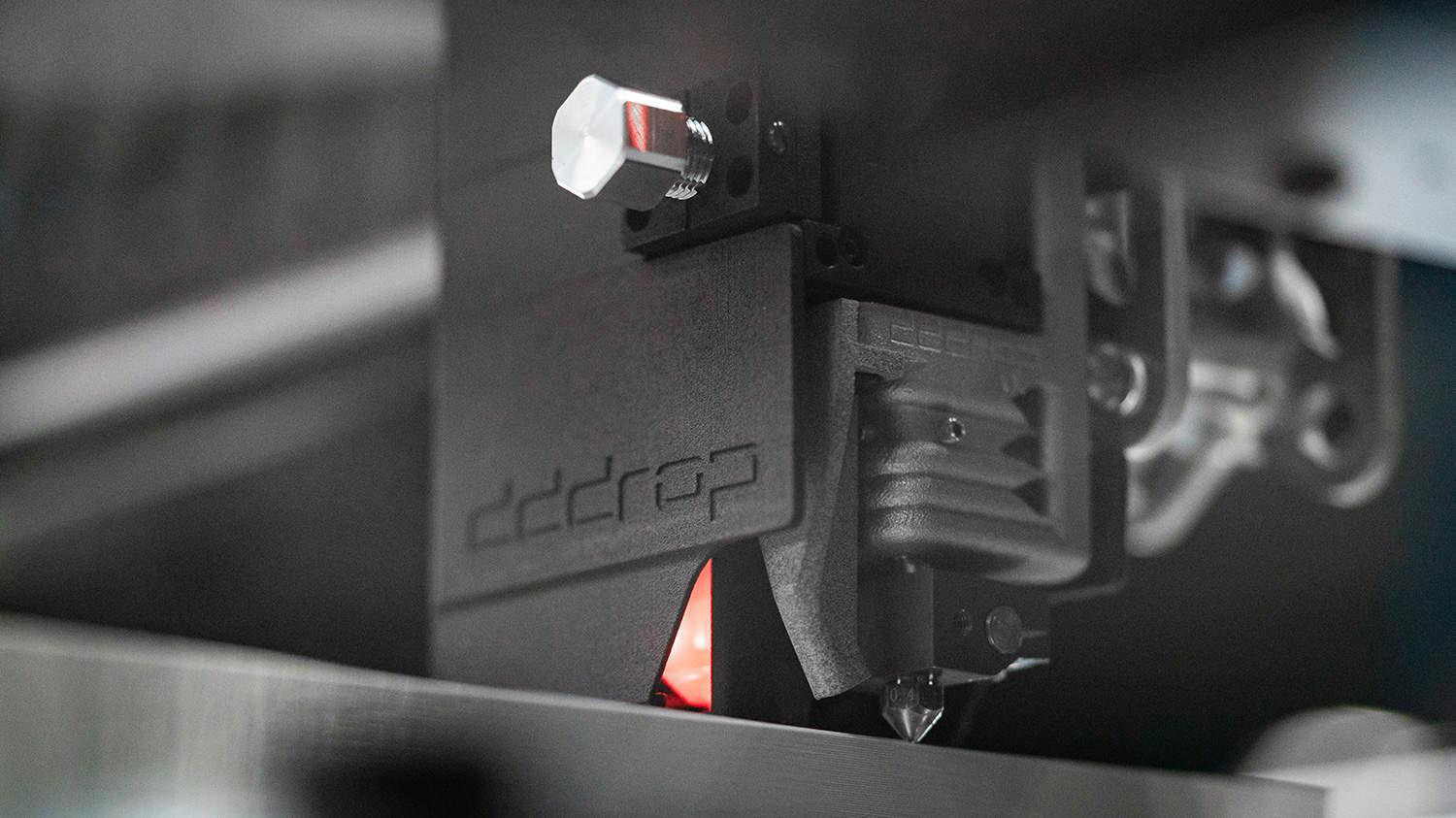

Model accuracy

Accuracy is one of the most important aspects of prototyping. When the prototype is identical to the final product in shape and functionality, developers can start experiments, test for design flaws, and get a better understanding of the functionality.

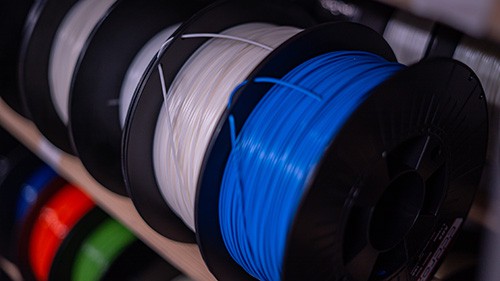

Material variety

Rapid prototyping

Compared to outsourced 3D printing or other methods of prototyping, in house 3D printing is much faster. Developers are able to rapidly and repeatedly print variations of products to test different iterations and technologies. Decreasing the prototyping time means reducing the time to market.