What is 3D print delamination?

We talk about delamination in 3D printing when a shrinkage occurs higher up in the print model, during 3D printing. When and how fast a product shrinks depends very much on the type of material you use during printing. PLA and PET-G are not sensitive to this, but when you use more complex, shrink-sensitive materials like ABS or FLEX, there is a greater risk of shrinkage and warping. For example, when the material cools down too much during the printing process.

Difference between warping and delamination of a 3d print

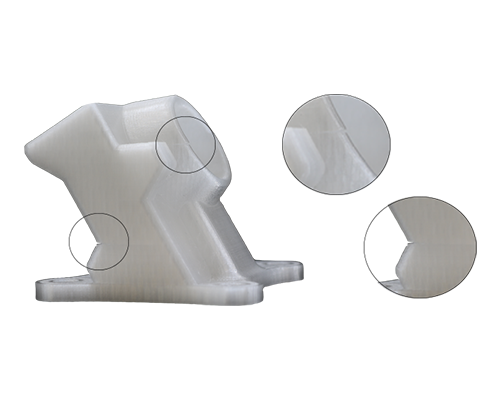

Warping can occur in two places in the model. Firstly, at the bottom of the product, i.e. directly on the print bed. This is called warping and it occurs frequently. Various methods have been developed to prevent this. Second, delamination; two layers in the model pull away from each other and a crack appears. This is mainly due to adhesion errors. When the right settings are used for the right material, delamination should not occur.

Room Control

When printing with highly shrink-sensitive materials, printing under the right temperatures and space control is very important. Of course, a closed environment is essential for this. This keeps the temperature in the printer cabinet stable. But with room control, with which the dddrop RAPID ONE is equipped, it is continuously checked whether the cabinet temperature is stable or whether it needs to be adjusted. Only if it is really necessary is air supplied from outside. The RAPID ONE thus has a conditioned space.

Blockage of the nozzle

Another cause of delamination can be that the nozzle becomes clogged because the correct settings are not being pressed. This may be because too much material is being squeezed through the nozzle too quickly, while the temperature is set too low. This results in an extrusion that is too low. The result is that the layers are not built up properly: too little material is applied, so the adhesion is not optimal. In this way, the chance of cracking the model increases.

Delamination is an adhesion problem that we only see with very shrink-sensitive materials where the print settings are not properly adjusted. With its chamber control, the RAPID ONE is the ideal printer for printing shrink-sensitive materials.