The advantages of flexible filament

Printing with an FDM 3D printer offers more and more possibilities. In the past, PLA filament was by far the most widely used material, because it is cheap and very easy to print. Now we see the use of other types of filament increasing in the market. Due to the ease with which we can 3D print models and parts ourselves, there are increasing demands on the material. The models are used for more and more applications, for example small series of products or machine parts. In short, the 3D printer market is developing rapidly and there are now various types of filament (printing material) on the market, so the right material can be used for each application.

The dddrop 3D printers are specially developed with an open system and offer complete freedom of choice in printing material. This means that you are not only free to choose your supplier, but also the type of material you want to print. The closed housing and heated print bed make it possible to create models from all kinds of materials. In this article we highlight the flexible filament TPU.

Flexible filament

Flex filament is a collective name for all the flexible filament on the market. These filaments are also known by the name TPE (thermoplastic elastomer). There are different types of TPE, of which thermoplastic polyurethane (TPU) is the most commonly used among 3D printer filaments. As the name suggests, this material is elastic in nature, so the plastic can be easily and extensively stretched and bent before breaking. In addition, it has a high temperature resistance and thus can be used in high temperature environments. The material is best described as the perfect balance between hard plastic and silicone. It is a combination of the beneficial properties of both materials, making TPU flexible, but dimensionally stable, unbreakable, dust resistant and barely scratchable. In addition, this material can be completely transparent.

TPU filament is easy to print

Of the flexible materials, TPU is the easiest to print, because it is relatively a hard flex filament. The “softer” the flex filament, the harder it is to print. Using a special soft spring to guide the filament to the print head, the right print settings and a clean nozzle, it is easy to print a flexible product with TPU.

Applications of TPU filament

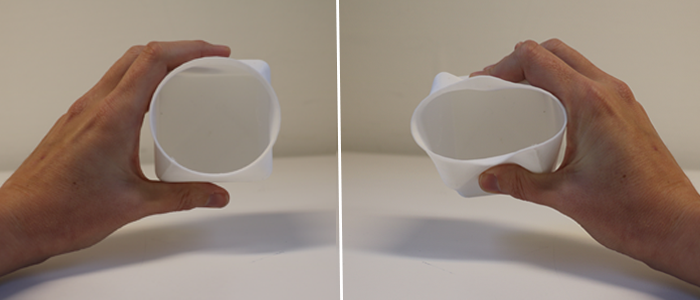

TPU is used for shoe soles, for instance, but also for pads or other shock-absorbing applications. We also see many applications for closing off certain sections by means of, for example, cover rings

A frequently asked question is whether it is possible to print with rubber. Printing with rubber is not possible, but TPU or other flex filaments can be used for rubber-like solutions.