Can 3D printing be used for production?

Why 3D printing?

Reliability

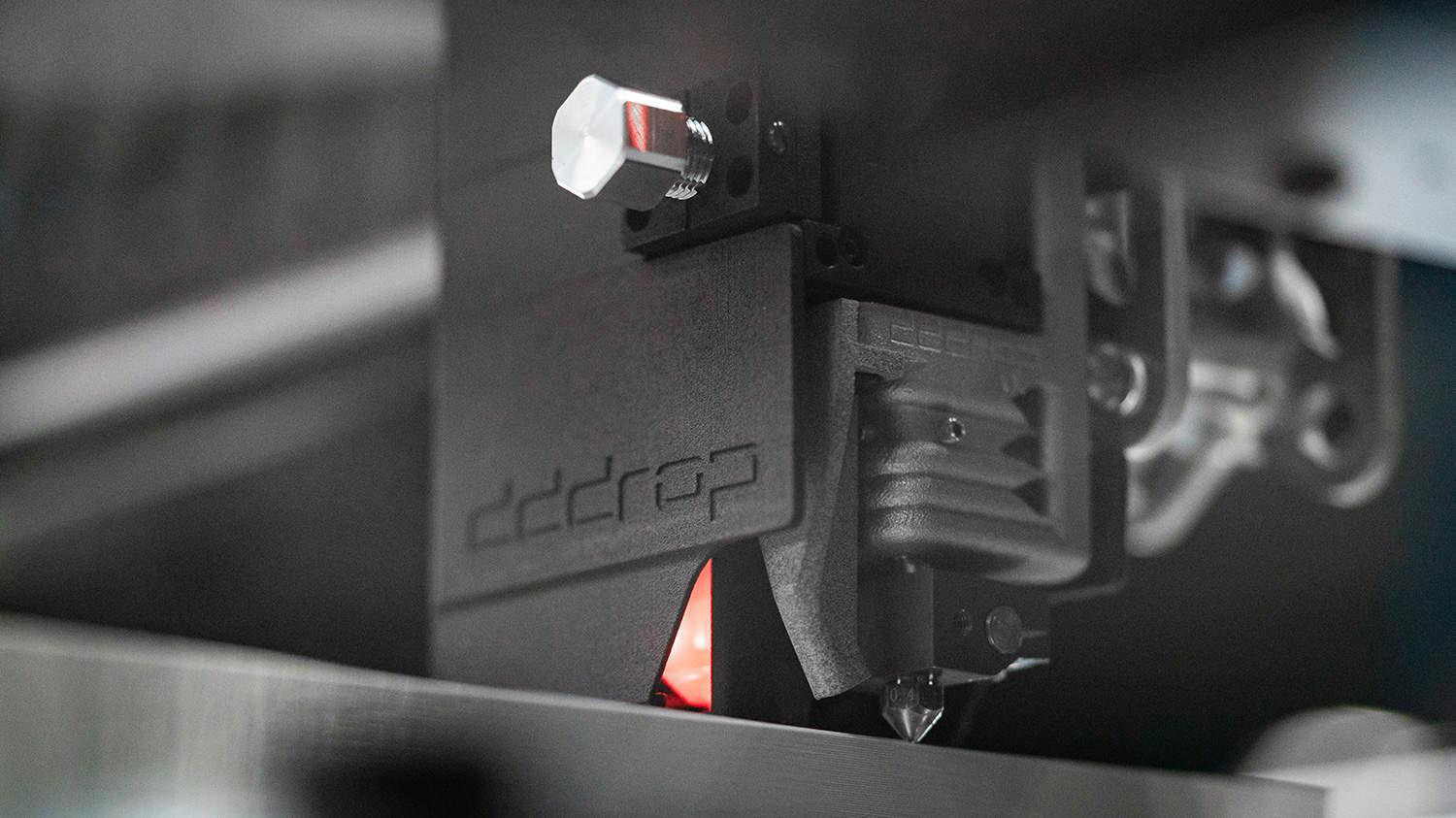

Printing accurate models time after time, with minor to no variability, for long periods of time became a mission for the dddrop RAPID ONE. 3D printing is no longer a hobby for engineers and enthusiasts. It is now a production tool businesses and manufacturers can rely on.

Speed

Production means meeting deadlines, and deadlines require speed. New technologies allow faster movement of the print head and a greater extruding volume. This allows the machine to lay down large amounts of material and produce at a speed suitable for production and manufacturing applications.

Preparation

When using 3D printing, manufacturers review the preparation time and efforts needed in order to analyse bottlenecks in production. Integrated filament dryer, swappable glass plates, and quick release print heads allow fast equipment exchanging preparation for production.