Can 3D printing be used for end-use products?

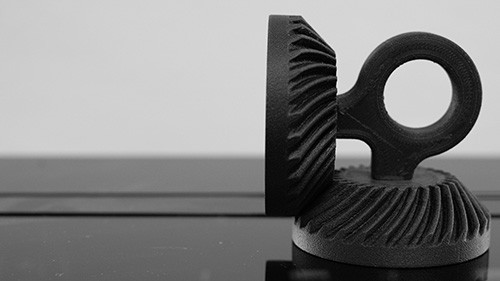

Using 3D printing has allowed designers to experiment with more sophisticated and complex designs that were unattainable using traditional production methods. 3D printing unlocks the ability to produce custom made products and parts of all complexity levels that can pass quality control standards and become functional components in end products.

Why 3D printing?

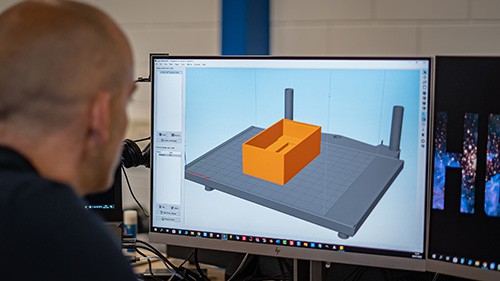

Design Freedom

3D printing offers the ability to imagine a product design and its qualities, as well as rapidly bring to it life as a physical object. 3D printing frees designers from the limitations of traditional product manufacturing techniques and allows wider possibilities in product design and functionality

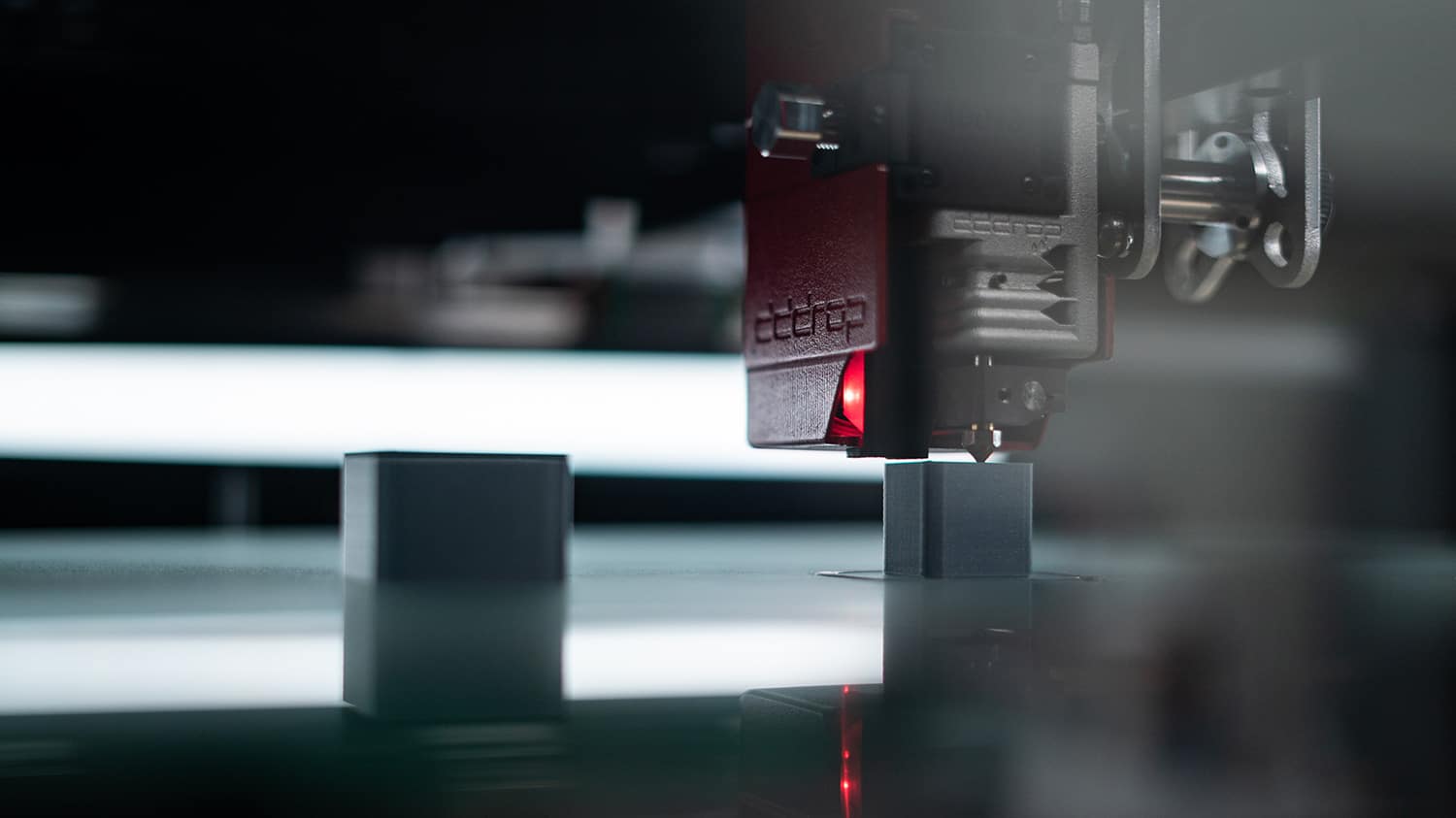

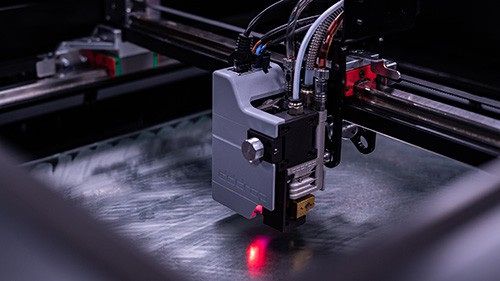

Efficiency

Efficiency is a major theme in 3D printing. It is expressed in minimizing material waste, unlike other commonly used technologies, such as CNC, which can be extremely wasteful. Besides, 3D printing is more time-efficient in preparation and maintenance, than for example, injection molding.

Materials

3D printing allows the use of many different materials with different properties, allowing the model and the final product to be either stiff or flexible. These materials allow greater possibilities and versatility in designing and manufacturing end-use products using 3D printing.